Yes Dan, it adjusts the pre-load on the side bearings. Would it be possible to drill and tap the cap and make a locking plate to locate in another slot in the ring, then Loctite a bolt in? Maybe two bolts to stop the plate turning.

Pete.

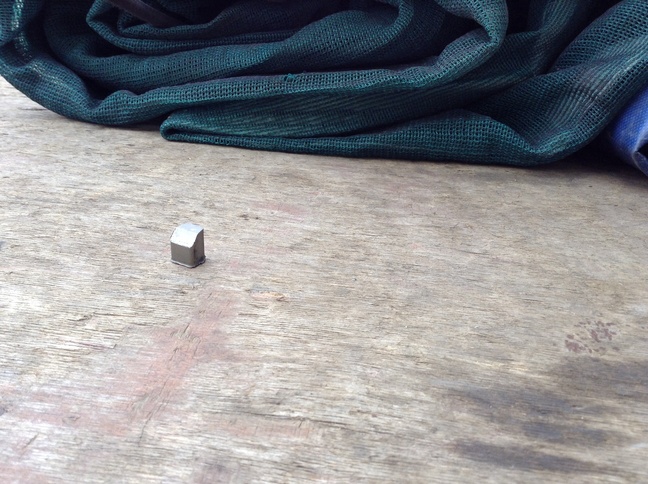

May be Pete ,but being as this has only done 500,000ks ,iam thinking of getting a new ring fitted at a reconditioners ,they can’t be much money ,until I saw where it had come from I thought it was out of the planitary gears .( it’s on the patio come do it me pete ) .

Dan Punchard:

May be Pete ,but being as this has only done 500,000ks ,iam thinking of getting a new ring fitted at a reconditioners ,they can’t be much money ,until I saw where it had come from I thought it was out of the planitary gears .( it’s on the patio come do it me pete ) .

Sorry Dan, washing my hair this week… ![]()

Pete.

The collar rings are used to adjust the depth that the crown wheel teeth mate with the pinion teeth which then sets the lash.By tightening one side and slackening the other you can get the correct settings Usualy about 10 degrees of the pinion flange.You have no pre load on the diff carrier bearings.

On a new crown and pinion you would use engineers blue to mark the depth of the tooth mesh but with a used unit you cant really do that.One castellation is neither here nor there just tighten the ring to the next land.

One other thing is that some rockwells have a kick bolt that runs against the back oi the crown wheel to stop tooth jump under heavy load.You have to make sure that is about 5 thou clear of the crown.

Have you found the bit that looks missing in the casing, as it doesn’t actually look like any movement is going on in use from the photo?

stick weld ■■? I thought it was chuddy gum ![]()

![]()

![]() joking aside did you use the correct rod ? the material appears to be "cast steel " I wouldn’t like to think you had a lump of weld floating around in there .no doubt someone with more knowledge than I will make an informed contribution.

joking aside did you use the correct rod ? the material appears to be "cast steel " I wouldn’t like to think you had a lump of weld floating around in there .no doubt someone with more knowledge than I will make an informed contribution. ![]()

I think malleable cast by the way it welded so not too bad .

Was going to say if it was one of my own trucks that I would probably try and put a blob of weld on. Bit of a worry what caused it to go in the first place, hopefully just a flaw in the original casting.

According to well known reconditioner it’s not uncommon ,they said they would happily take £50 off me to adjust it to a different position ,but not fit a new ring ,they also said not to worry too much and pop it back in ,to my mind the crown wheel to pinion adjustment is fine as you can hear it but not see or feel the back lash .

Dan Punchard:

According to well known reconditioner it’s not uncommon ,they said they would happily take £50 off me to adjust it to a different position ,but not fit a new ring ,they also said not to worry too much and pop it back in ,to my mind the crown wheel to pinion adjustment is fine as you can hear it but not see or feel the back lash .

Bargain! 50 quid for jack!Count me in as a “reconditioner”

[zb] beats brains every time