Tell more, I always assumed they did it as we did.

I meant the traditional British dolly where you do the business as usual and are left with a loop at the bottom which you place over the hook and then pull the loose bit (which isn’t an end because it continues to the next one) hard down tight before securing with a half hitch (I think it’s called).

You can’t do that with an Aussie trailer because it is a long bar rather than a hook and thus the loop cannot be placed over it. The way to do it, as you know, is to make the hitch by passing the loose end of a short rope under the bar and then making a similar hitch above it but for some reason you must take more care because the ‘rabbit ear’ at the top can bend down and allow the whole thing to disintegrate.

IMO the British way was better except for the fact that you could only make a crossover in specific places, rather than anywhere along the bar, if you wanted them to be perfectly vertical. I never had to do an Aussie hitch myself because in road haulage there I was only loading and transporting cows which objected to being tied down ![]() but as a professional I wanted to further my knowledge so learned how to do it anyway.

but as a professional I wanted to further my knowledge so learned how to do it anyway. ![]()

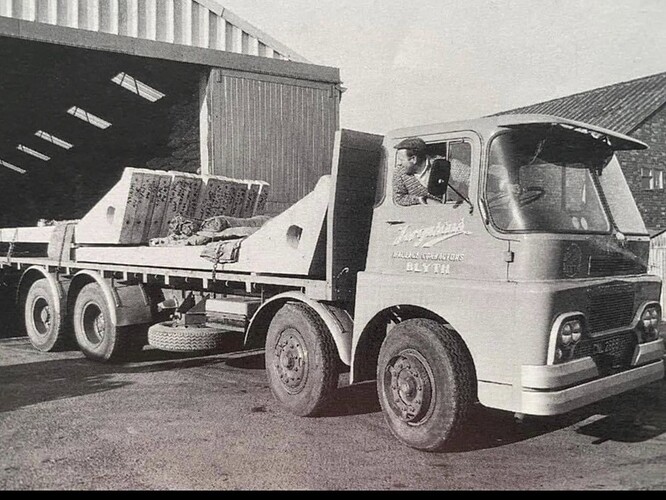

In the early 80’s when we were pulling SCAC trailers a lot of the loads were pellet plastic granules on pallets, the Frogs did not know how to do a dolly and were sent out with a coil of new rope every load, they would tie the end off and throw over the load and leave enough on the end and cut the rope, then they would tie an ear about 2ft up put the end round the hook, oh yes there were hooks then pull it down and tie off. This was done the entire length of the load so when we UK drivers delivered all we ended up with was a load of short ropes with ears you could not get out as they were so tight. If we reloaded we had to tie them together as best we could to make do, Mary Hopkins moments them, Buzzer

I would make one small point. It is possible to move the line of the rope away from the hook, but that is slightly more involved and takes a little more time.

.

Either do “a spreader” on departure (make your innuendos) or a double dolly on arrival across two hooks.

Probably the most intelligent comment on this subject I’ve read IMO. In the pi $sing rain doing multiple drops of board around a city with a flat-bed 14tonner (23T GVM), untying/ retying tarp (sheet) ropes multiple times your fingers get raw very quickly. And it’s not fun.

When I was taught about roping and sheeting the driver who helped me said “It is harder at first to do it with gloves on, but do learn with gloves on, rather than make it harder for yourself later”.

Seems to make sense to me. The gloves don’t stop all hand damage, but are an aid.

It’s the actual roping which i couldn’t use gloves for.I always ended up with a glove finger trapped in the rope.Taking them off was no problem and wrapping sheets up again i always used gloves .In winter which you will know about and SDU will have seen on Xmas cards ![]() take the ropes off wrap and roll the sheets up then end up with soaking wet gloves and frozen fingers.Gloves on the demister fan on full blast window steamed up next drop gloves rock hard arthritis in the fingers.I still get fingers locking now.Oh how i miss roping and sheeting … not

take the ropes off wrap and roll the sheets up then end up with soaking wet gloves and frozen fingers.Gloves on the demister fan on full blast window steamed up next drop gloves rock hard arthritis in the fingers.I still get fingers locking now.Oh how i miss roping and sheeting … not

I used to do that a lot. That brought back memories. Remember the collection of “once overs” everyone carried to save using a fresh rope? ![]()

Although I do agree with that very much there is still the lack of the feeling of looking back at a job well done isn’t there?

Probably more like the nice warm feeling… after banging one’s head against a brick wall for an hour.

![]()

The problem was when it was wet (it always seemed to be raining) the gloves got wrecked by the ropes, the finger ends got trapped and the gloves just basically disintegrated. Callouses were the least of my problems though, I was more concerned about the dirty freckles all over my face from pulling down on the wet rope!

We swopped trailers a lot, but they tended to have 5 full skeins and one smaller one.

Normally had a couple of spare skeins hanging on the back of the cab too.

Helped out in the yard a few times making skeins from full coils of rope.

Did we get 3 skeins from a coil? Decades ago now!

We used to splice eyes in both ends of ropes. Tied one end to a warehouse girder or trailer, and t’other end to a forklift, then pulled them to get the stretch out of new ropes.

New ropes??? i used to get castoffs from McCoreys? of Morecambe. They loaded where we were based for Ireland and had endless supplies of ropes

Ropes you say, we had to use dental floss or an old G string.

I Had those nets made to cover the whole load of bales from the Rexam plants ( formally Bowater Packaging) They were very light and believe it or not they didn’t let much rain in either.

We had nets for some loads, but they were not part of every trailer’s kit.

our nets were not a wide as yours, and we used them on natural stone/bricks/roof tiles etc.

Some drivers them used on barrels but the net got trapped in between the barrels, and it also allowed water to gather on the top of the barrels. Not a good move IMHO.

Certainly lighter and easier than a set of sheets, and kept decent sheets away from rough concrete etc.

Were they rectangular with no flaps , they are what my dad said he should have had instead of the lightweight ones he used

You have to keep your fingers at the correct angle so that when you pinch the rope ( or hoover cable ) to make the head of the dolly and the loop for the neck and making the twist for the pulley your fingers don’t get in the way of all the rope paths.It’s easy with a bit of practice.

As for paper reels I was sceptical about the stupid roped single back ‘scotch ’ block stopping two stacks of reels shifting backwards.I roped every row with an overall and around cross front and back.Then I used the convenient front and rear rope hooks of our stripped tilts to run two parallel full lengths front to rear.

‘Then’ I also roped over those side to side, between the rows, in a similar way, but to better effect,

as roping a sheet between the rows in a laughable attempt to convert the tension and tensile strength of rope to a sheet of canvass.

Got it from a book indeed.

Carrying those zb things on the roll still scared me zb less.

So after all that and Franglais’ correct comments why all the needless hostility.

You use closed bars we use/d hooks.

It follows from there.

If you look closely at my example by magnifying it you’ll see the loop at the bottom which is/would be placed over the hook ( if it was a truck not a door and a rope not a power cord ).

Although maybe I could have used the door handle if I wanted to tear it off the door and wreck the hoover cable.

Then pull the end which runs through the knot to make the rope pulley as usual then twist that length into a half hitch around the hook.Run the rope along to the next hook twist it into another half hitch and chuck the rope over to the other side and make another dolly on that side alternating side to side along the deck.Hooks obviously make that process easier than closed bars.

Some day you use lots of separate lengths of rope and feed them around the closed bar and lock them one at a time for every pass.

The difference is that dollies should be locked with a full hitch and I never trusted half hitches anywhere because if any of em get loose or move it compromises the whole lot.I locked every pass and every dolly with a full locking hitch on every hook.

I also liked to use double dollies which was a good test of ropes and useful for tying down stacks of empty pallets.It actually doubles the leverage of the rope pulley effect.But the first one needs to be started high, by standing on something if you’re short like me.

The hooks were generally just big enough to take all the required rope lengths and diameters for two Dollies and a locking hitch.

That might work even better using your bar system.

Maybe Ramoan could tell me which book told me all that.

Certainly not Bewick’s book I’d have been in hospital needing skin grafts after a week doing local multi general.