Someone on here will have been 5 nights a week out in one of those no doubt ![]()

Heavy pallets loaded with fragile goods with equally fragile packaging.Too fragile to be roped or strapped.

The drop sides of a tilt, combined with webbing cargo nets, will provide a lot better odds of ‘securing’ and containing such a load on the load deck, than relying on the strength of a sheet of canvas to hold it all on a flat.

Obviously if you’ve only got a flat and some ropes and sheets it’s your call.You said the latter choice is superior.The fact is ‘securing’ a load is the same whether it’s a curtain sider or a tilt or a flat.

Generally, with the exception of overhead loading, a tilt saves lots of work in sheeting just like a curtain sider.

Obviously anything I took out of the yard on a flat was on the basis of the ropes hold the load on and the sheets keep it dry.As opposed to relying on just a bit of canvas or plastic sheet to stop a paper reel or two from flying off the back at 40 + mph.I’m obviously referring to ‘my time’.

Using a sheet to ‘secure’ a load, such as roping between reels or drums to hold them with the sheet, was/is a cowboy practice.

The sheet is there to keep it dry or ‘contain’ the load the lashings ‘secure’ it.

Can’t be bothered to post the up to date DVSA instruction but it’s nothing new, any decent driver knew it and was taught it.

Collecting bottled water, the plastic bottles, a while back we were told to put two pallets behind the last two pallets in the upright position then ratchet strap it diagonally, the DVSA enforcement won’t accept this method now, you can’t put a ratchet over every single pallet as it will crush the bottles.

I have seen a load of bottles covered with empty pallets on top of the bottles then strapped down.

Or a load of chocolate, the straps would crush it and be rejected at the delivery point.

I rarely bother to indulge in your haplessness by commenting on it. It’s much easier to simply sit back and watch you make a complete buffoon of yourself with no outside help.

The problem is that your “knowledge “ has been gleaned from snippets you’ve read or overheard. Your lack of real world experience is glaringly obvious and quite frankly embarrassing to watch.

Sometimes it’s best just to shush and let the grown ups talk.

Roping between pallets wasn’t a cowboy method it was how it had to be done and was quite safe. No chance of that

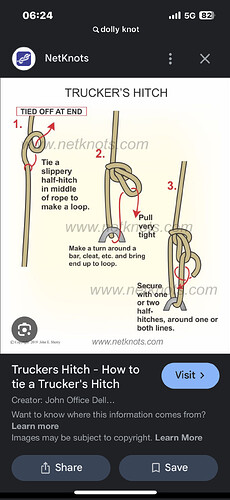

I wonder if CF could have done a dolly knot.

You keep quoting DVSA or VOSA.It was the Ministry men who were out there before curtainsiders when most trailers were flats.Tilts were in the main used for continental work and some firms may have used them for the odd job here and there where convenient on domestic work. Your termonology shows how much you google. “Lashings” ffs.I posted a photo a while back of an 8 wheeler and trailer loaded (hand balled) with heavy cartons of yarn. The outers at both sides placed on the raised chock rails so they leant in.Well over cab height not a pallet in sight.Heavy sheets over kept tight then roped down .If it was a dry day would you leave the sheets off , no way.Your way of doing it is what’s happening where i work.They come in with empty curtainsiders load 25 - 28 ton of waste bales 2 on the floor side by side then 2 on top.They then leave a gap and do the same again all the way to the back.It makes me cringe.The drivers throw a strap over each row and off they go. As soon as they’re off the bales start to settle as the leachate runs out of the bottom.The straps won’t stay tight.The gaps between are for the dockers who unload them to get their clamps in so they don’t tear the wrapping.An accident waiting to happen as the bales will move forward and backwards under braking and accelerating.They’ve got away with it so far but they will come unstuck.You have no idea whatsoever

He would think that was a dance

If tilts were still around today, the side supports which look long metal doors, would not be accepted as load security.

I may be wrong but I’m sure CF mentioned using the sheet of the tilt to put over the load if the tilt has been stripped down, a tilt can be fully stripped down to turn it in to a flat bed trailer but the sheet would weigh a lot and could not be manhandled by one person.

At a guess at least 800 kg’s.

Most of the time any staff at the customer’s premises would refuse to help as they had other things to do or it was close to knocking off time.

If I rang any drivers in the area they would say they can’t help as the back is playing up.

Another issue is trying to lift or move a tilt sheet in extreme temperatures or in the winter and the rain has frozen on it to add extra weight.

The support bars at the side would not be acceptable for load security at this point of time, the support bars would always be seized up, so the fork lift driver would have to adjust the load to place the pallet around the stuck bar, which could leave a gap in between the pallets, so braking hard in an evasive manoeuvre would mean the contents of the pallet shooting forward and spilling out on the trailer floor.

Using a tilt on a multi drop was not fit for purpose as the driver would complain it takes too long to keep removing the wooden side boards at the side of the trailer.

You would need two people to get the side sheet fully open as you could not open both sides at once, at a push it would take someone ages to open it alone but mean walking to one side of the trailer to the other multiple times to keep pulling up the sides to access the front of the tilt.

Most tilts were step frames, the one’s we used at British International were called SJ’s or super jumbo’s due to the extra volume and capacity of the trailer which customers liked as they could get more shoes in the trailer.

If I was told the load was a machine for delivery or for a reload,or an old printing press, I would dread it as know it was only an overhead crane that could load or reload the trailer and the trailer roof would have to be opened up.

I would insist that enquiries must be made if the customer has the right equipment to unload or load the trailer and it is actually working, if not, don’t send me out with the load or find another reload even though that could be waiting around for a few days when the office was ringing around to their contacts and import/export agents to find one suitable.

The overhead crane would always rip out the eyelets that are used to thread through the CMR cord used to seal the trailer in the days before the borders closed.

If you could not seal the trailer properly with gaps where the cord can’t go through properly , the customer would not be happy as someone could reach inside the trailer to steal their goods.

Sometimes the trailer would be rejected for the office to find another driver with a suitable trailer.

For some reason some customers didn’t trust drivers with their load, as an example if you loaded a full load of slippers or shoes, the manager would give the driver a free pair, did he think, if he didn’t, that a driver would break the CMR seal, take out a pair of shoes for himself, reseal the trailer, put a new seal on it then record the new seal number on the CMR ?

On delivery, any changes to the seal number were only acceptable if the CMR had an official embossed stamp on it by customs as they could open the trailer to inspect it to make sure the declaration of the description of the goods tallied up to the CMR.

Or inspect it for any items smuggled in from Europe, or the customs in Europe could break the seal to inspect the load.

Ramone is correct, it was the ministry men or department of transport inspectors , and definitely not VOSA at the time period that CF has mentioned.

DVSA back then didn’t exist as a government body or agency.

A Morris Minor dance to the Wurzel’s as the backing singers, I’ve got a brand new combine harvester.

How would CF cope with these factories that load these horrible wooden sheets that are later made in to kitchen cabinets or other products?

They are loaded in three levels or stacks so you have to put a ratchets on each level of the load, so two ratchets on each stack as they are not on pallets as they put wooden blocks under it for the fork lift to get them out at the delivery point.

The load will be touching the trailer roof with no room to throw a ratchet over the load.

Unless you put the ratchet on the stack before the fork lift driver puts it inside the trailer, or when he is not looking as you are not allowed to stand inside the trailer in the loading process, get a ratchet on it by somehow sliding it down with a long pole.

That’s six ratchets on each level, or about 30 or more by the time the whole load is fully secured and adding more for peace of mind.

On the journey, the load is constantly moving as the sheets are slippery.

It’s necessary to keep the ratchets tight at every stop, if you see the load bulging through the curtain you have to hope it won’t move anymore as that’s a red flag for the CVU or DVSA to pull you over.

Even if this means standing in the hard shoulder of a motorway to tighten the ratchets, hence why I always have the tightening mechanism on the near side and not the offside as that means getting too close to passing traffic in the live lane, some drivers choose to put them on the offside so they can keep an eye on them in case they become loose in transit.

Formica was notorious for moving

Formica, that’s the one, a right pain.

Another place was in Wales and near the Scottish border that was laminated boards, I could be hours to all day in these places with 20 lorries in a queue to load and they didn’t load them quickly with multiple tea breaks and shift change overs or took their time on purpose.