Ive looked all over the threads for anything on Barber Turnock and found a photo on here,used to do a yard to yard change over with them in the early 70s when working for Tayforth Darlington,Vic

All you lads get misty eyed about your Atkis, Now dont get me wrong Im not knocking them I never had the pleasure (apart from me Stato) even though I started driving for a living in1969 but it strikes me the only part of the Atki that was Atki was the chassis & cab the rest made up in diferent combinations of ■■■■■■■■■■■■■■■■■■■■ /eaton /Kirkstall David Brown etc etc . The same going for ERF, Foden,perhaps this is where the success of Volvo Scania etc where the whole wagon was designed & made with their own bits to a large extent, & so put the Uk trucks makers into decline.

Just a thought Ive had for yrs (by the way loved me Sed Atki 410 ■■■■■■■ eaton twin split just in case you my think Im anti Atki)

We had the sister to this one at Tayforth Darlington it could climb a wall but you needed ear plugs to drive it!!

greek:

All you lads get misty eyed about your Atkis, Now dont get me wrong Im not knocking them I never had the pleasure (apart from me Stato) even though I started driving for a living in1969 but it strikes me the only part of the Atki that was Atki was the chassis & cab the rest made up in diferent combinations of ■■■■■■■■■■■■■■■■■■■■ /eaton /Kirkstall David Brown etc etc . The same going for ERF, Foden,perhaps this is where the success of Volvo Scania etc where the whole wagon was designed & made with their own bits to a large extent, & so put the Uk trucks makers into decline.Just a thought I

ve had for yrs (by the way loved me Sed Atki 410 ■■■■■■■ eaton twin split just in case you my think Im anti Atki)

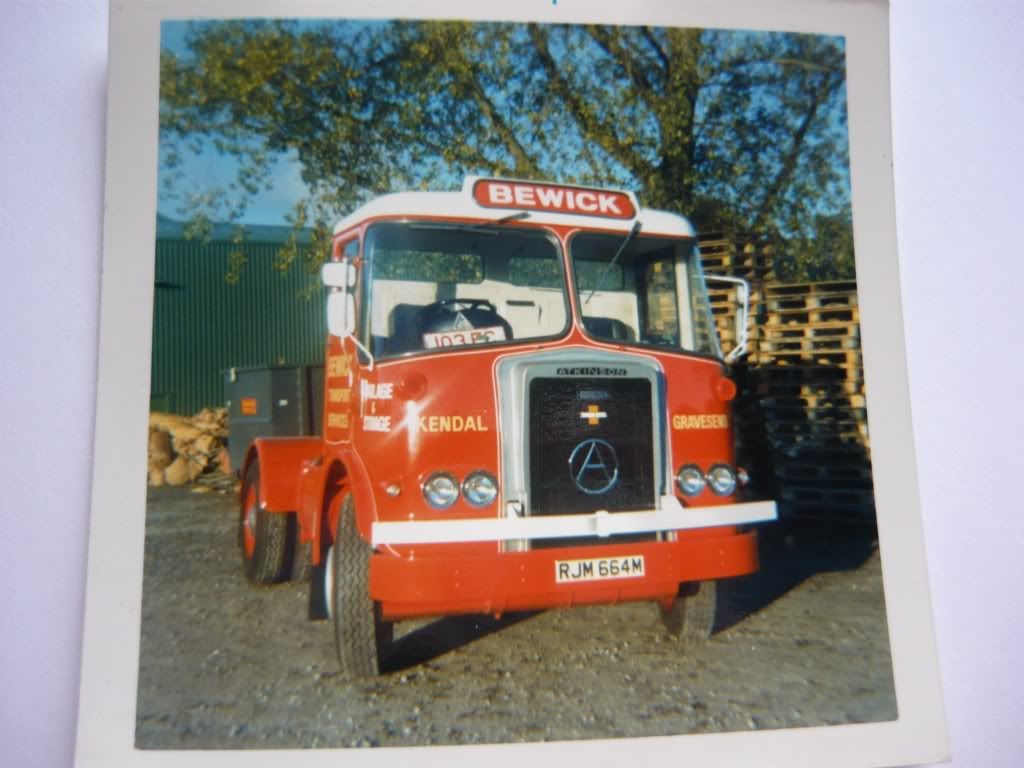

Your observations are correct “greek” as Atki’s ERF’s and Foden( to a lesser extent than the first two) were what can be described as “vehicle assemblers” of propietry components and Scania and Volvo were what can be described as “vertically intergrated” vehicle manufacturers.There was nothing wrong with being an assembler if the driveline spec was perfectly matched,as it was in the main.But when there was component shortages the “ideal” specs went out the window as the assemblers scrambled to keep their production lines running with whatever they could source.Whereas the “intergrated” manufacturers were able to keep operating with perfectly matched specs,as they built their own drivelines from scratch. Then again in Atki’s case when Seddon took them over and proceeded to srew them up, one of the biggest mistakes was to impose their Group axle on Walton-le-Dale which at times was all you were offered on a new chassis.However I will say that the last two Borderers we got at Bewick Transport in late '75,one had a Kirkstall HR axle/ Fuller 610 and it’s mate had an Eaton 2 speed/ DB 6spd.Both were 220 ■■■■■■■ engines.Cheers Bewick.

Stanfield:

Found this one from a thread which was put on here in 2005 (so I borrowed it I hope they dont mind)

240 gardner check out RDC141M note the headboard name panel missing same has Sadlers RDC139M.10 could it be it once was one of Sadlers like you said? maybe.

I presume it has a clear perspex headboard rather than an opaque one. I’ve no idea whether 141M was ex-Sadler, but it’s not far out on the reg., is it?

Here are some classic 8 wheelers for you…

The green cabbed Defender was operated by Keith Higginson of Earl Shilton. A staunch Atki man, and this example from his fleet had just had a brand new alloy body fitted after the first one wore out!. All his Atki’s were named after his daughters as I recall.

Not many old chassis got a second new body, but quite a few old bodies were fitted to new chassis in those days!.

The blue one is photographed at TIPCON in 1974.

Saviem:

…still a 9ft 6in wb (boing boing ride)…

Early in January 1993, I took Bowker 47, a Mk.1 tractor with the aforementioned 9’ 6" wheelbase) down to London to participate in the funeral of its former driver, John Hemelryk.

It was the first time I had ever been on the newly-opened section of the M42, between the M5 and the M40. I discovered that the joints in the concrete sections of the road surface were just the right distance apart to bounce the drive wheels into the air whilst bobbing along at the nominal geared speed of 49.5 mph ![]() I had to drop it to about 38 mph, as I remember.

I had to drop it to about 38 mph, as I remember.

Still, it went down to Kensal Green for the funeral, across to Paddington for the wake, and back to Lancashire that evening, at an average fuel consumption of 18.5 mpg. Bill & Ken Bowker travelled down on the train, and Bill did point out that, had he driven there in the BMW 850 V12 Coupé that he was running at the time, it would have used more fuel than the 6LXB!

Bewick:

Your observations are correct “greek” as Atki’s ERF’s and Foden( to a lesser extent than the first two) were what can be described as “vehicle assemblers” of propietry components and Scania and Volvo were what can be described as “vertically intergrated” vehicle manufacturers.There was nothing wrong with being an assembler if the driveline spec was perfectly matched,as it was in the main…

Quite right Dennis.

We should always remember that the vast majority of trucks in the USA are also assembled this way - in some cases using exactly the same components as our UK wagons - ■■■■■■■ NTE, Fuller 11609, Rockwell R180…etc.

In America the opposite to mainland Europe seems to have happened, in that the fully integrated manufacturers have fared worse than the component assemblers. In Europe, as you say, MAN, Volvo and Scania have survived and dominated.

In the UK, AEC, Leyland and Foden are the only major builders that I can think of that made every component in house, the latter two to a much lesser extent in the later years, but unfortunately they still all failed to keep their footing in the marketplace. Whether that was because of poor business management, lack of product development or whatever has been the subject of road haulage debate for the last 30 years, and I suspect will be for the next 30, but what is for sure is that all of the UK manufacturers at one time or another had an excellent product that could have prevailed.

When the bean counter accountants get involved in the business of engineering and manufacture, you always get imposed decisions - like fitting the SA group axle - by people who would not have a clue if it was fit for purpose or not. Ignore the R&D engineers, if it’s cheaper - fit it!. And that is exactly how manufacturers reputations are lost.

While we’er on about the “infamous” Group axle,which was reasonably OK behind the 180LXB Seddon 32/4’s but a complete disaster when behind the bigger engines,it always baffled me how this axle was rated at 13 ton as that in itself implies that it was supposedly designed to operate at much higher GVW’s than 32 ton ? Dennis.

We had some Sed Atki 400’s with 265 rollers that had that poxy axle,you was lucky if you could go a month without a hub seal leaking or hub reduction gears collapsing, the latter often being a suspend tow in,luckily we had our own wrecker at the time.

Trev_H:

We had some Sed Atki 400’s with 265 rollers that had that poxy axle,you was lucky if you could go a month without a hub seal leaking or hub reduction gears collapsing, the latter often being a suspend tow in,luckily we had our own wrecker at the time.

We rekoned that the two 8LXB Sed/Akts we double shifted would do about 70,000 miles between axle re-furbs. Dennis.

Bewick:

Trev_H:

We had some Sed Atki 400’s with 265 rollers that had that poxy axle,you was lucky if you could go a month without a hub seal leaking or hub reduction gears collapsing, the latter often being a suspend tow in,luckily we had our own wrecker at the time.We rekoned that the two 8LXB Sed/Akts we double shifted would do about 70,000 miles between axle re-furbs. Dennis.

They were cheap spec brs motors, an engineer there once told me that they bought what the salesmen advised them to have ![]()

![]() !!!

!!!

Bet the salesmen rubbed their hands and dumped all the crap they could find on them. ![]()

![]()

![]()

As drivers we knew what the best spec motor was for the job but they always got the cheapest crap and other peoples rejects!

Trev_H:

Bewick:

Trev_H:

We had some Sed Atki 400’s with 265 rollers that had that poxy axle,you was lucky if you could go a month without a hub seal leaking or hub reduction gears collapsing, the latter often being a suspend tow in,luckily we had our own wrecker at the time.We rekoned that the two 8LXB Sed/Akts we double shifted would do about 70,000 miles between axle re-furbs. Dennis.

They were cheap spec brs motors, an engineer there once told me that they bought what the salesmen advised them to have

!!!

Bet the salesmen rubbed their hands and dumped all the crap they could find on them.

As drivers we knew what the best spec motor was for the job but they always got the cheapest crap and other peoples rejects!

Hiya Trev,bit wet for rioting to-night is it? Your right there mate the big outfits like BRS and the Oil Cos. always seemed to buy the worst spec cheapest tractors built Sed/Atk,ERF in particular with the RR engine and whatever the cheapest drive line was at the time.You never saw many private hauliers with RR engined motors,a few token ones here and there but that was all.I remember one of the cheapest 32 tonners was the Seddon 32/4 RR 220/DB6spd/Group axle.!! Noisey and nasty!! ugh! Cheers Dennis.

Bewick:

Trev_H:

Bewick:

Trev_H:

We had some Sed Atki 400’s with 265 rollers that had that poxy axle,you was lucky if you could go a month without a hub seal leaking or hub reduction gears collapsing, the latter often being a suspend tow in,luckily we had our own wrecker at the time.We rekoned that the two 8LXB Sed/Akts we double shifted would do about 70,000 miles between axle re-furbs. Dennis.

They were cheap spec brs motors, an engineer there once told me that they bought what the salesmen advised them to have

!!!

Bet the salesmen rubbed their hands and dumped all the crap they could find on them.

As drivers we knew what the best spec motor was for the job but they always got the cheapest crap and other peoples rejects!Hiya Trev,bit wet for rioting to-night is it? Your right there mate the big outfits like BRS and the Oil Cos. always seemed to buy the worst spec cheapest tractors built Sed/Atk,ERF in particular with the RR engine and whatever the cheapest drive line was at the time.You never saw many private hauliers with RR engined motors,a few token ones here and there but that was all.I remember one of the cheapest 32 tonners was the Seddon 32/4 RR 220/DB6spd/Group axle.!! Noisey and nasty!! ugh! Cheers Dennis.

You’re right about the wet bit Dennis, I’m in Kingstown tonight ,no rioters just wet spotters ![]()

![]()

![]()

Trev_H:

Bewick:

Trev_H:

Bewick:

Trev_H:

We had some Sed Atki 400’s with 265 rollers that had that poxy axle,you was lucky if you could go a month without a hub seal leaking or hub reduction gears collapsing, the latter often being a suspend tow in,luckily we had our own wrecker at the time.We rekoned that the two 8LXB Sed/Akts we double shifted would do about 70,000 miles between axle re-furbs. Dennis.

They were cheap spec brs motors, an engineer there once told me that they bought what the salesmen advised them to have

!!!

Bet the salesmen rubbed their hands and dumped all the crap they could find on them.

As drivers we knew what the best spec motor was for the job but they always got the cheapest crap and other peoples rejects!Hiya Trev,bit wet for rioting to-night is it? Your right there mate the big outfits like BRS and the Oil Cos. always seemed to buy the worst spec cheapest tractors built Sed/Atk,ERF in particular with the RR engine and whatever the cheapest drive line was at the time.You never saw many private hauliers with RR engined motors,a few token ones here and there but that was all.I remember one of the cheapest 32 tonners was the Seddon 32/4 RR 220/DB6spd/Group axle.!! Noisey and nasty!! ugh! Cheers Dennis.

You’re right about the wet bit Dennis, I’m in Kingstown tonight ,no rioters just wet spotters

I bet “H” is among them Trev 'cause he’s just “owned up” to be a “spotter” and he’s not on the site to-night so far!! Cheers Dennis.

I know its maybe not the thread for this shot but this was one of a number of Merc 300E’s that I ran and they were as smooth as silk just like the Atki’s and this particular '88 one was nearly the same fleet colour as the motors!

youd be rayt doing a bit of taxi ing round kendal wi that merc dennis an a few wedding jobs cheers bibs

BIBS:

youd be rayt doing a bit of taxi ing round kendal wi that merc dennis an a few wedding jobs cheers bibs

Yer don’t miss a trick you Ingleton boy’s do you!!! Dennis.

I think this tractor has featured eleswhere on the site but never mind! it belongs on here albeit in the “rouges” gallery section of the thread! This Atki cost me £250(in notes) over List price in late '73! I wouldn’t have minded but it must rank as the worsed spec Atki I ever bought! ■■■■■■■ 220/DB 6spd/Group axle and NO power steering! IIRC we double shifted the ■■■■■■■■ off it for 18 months and then got rid! Not before a gearbox rebuild and an axle re-con,when it went left us the engine was “breathing” out of the oil filler big time as well!! Bye bye,cheers Dennis. Oh! and not forgetting one other irritant on this Atki,as you can see from the photo,it had that little poxy steering wheel! OK with power steering but not good without! Dennis.

Oh! and not forgetting one other irritant on this Atki,as you can see from the photo,it had that little poxy steering wheel! OK with power steering but not good without! Dennis.

Ah yes, Atkinsons. Always a lorry many small hauliers aspired to own in the '50s and '60s, but by the '70s they were becoming dated and epitomised some of the best and worst features of British lorry manufacturing. Atkinsons were built, according to a haulier friend of mine, by wizzened old men smoking woodbines and wielding a four pound lump hammer backed up with a blunt hacksaw. Probably a bit of a harsh summary methinks, but I know what he meant.

Despite the criticism of Seddon and its takeover of Atkinson in 1970, the Oldham firm did recognise Atkinson customers’ loyalty to the marque and kept the Borderer in production for another 5 years. The late Frank Whalley did tell me that Seddon and Atkinson could not always build to a customer’s requested specification because of component supply shortages and problems in the early '70s, so to keep the production line going they fitted what was available.

By the way, before Seddon completed the takeover of Atkinson negotiations were well advanced between ERF and Atkinson for a merger, but Seddon was able to complete a deal because Leyland had 30% of the Atkinson shareholding and preferred to sell its shares to Seddon rather than ERF. Yet another example of Leyland helping to destroy thje British lorry manufacturing industry.