We thought we’d add a bit of clarity regarding both the regulation and engineering to meet the LST requirements.

Firstly, in order for a normal length trailer to be “deemed to comply” with the inner 5.3m turning circle regulations, the wheelbase (kingpin to centre of bogie) cannot exceed 8.135m. This is calculated using geometry if the cab front is skirting inside a 12.5m outer turning circle. In reality, a standard trailer will cut into the 5.3m circle slightly due to scrub effects.

Typically, we manufacture with a wheelbase of 8.1m (1.310 axle spacing). Some are slightly shorter at 7.8m or 7.9m for extra manoeuvrability.

When Longer Semi Trailers were introduced, the “Deemed to comply” regulation was overturned in favour of physical compliance. This meant that the wheelbase had to be slightly shorter so the wheels did not cut into the 5.3m inner turning circle.

This becomes a little complicated because, uniquely, an LST has 2 bogies: a fixed front bogie (typically a standard tandem setup but can be a single axle with the centre set at approx 7.9m wheelbase) + another bogie (single steer or tandem steer axle) set further back to cope with the rearward shift in weight so as not to overload the axles.

This means that, to prevent massive scrub on the fixed bogie tyres, the rear bogie(s) has to be steered. The most common, cost-effective, type is self steer but these are tricky when reversing as they don’t easily self-lock in tight yards. The other solution is positive steer (Not command steer found on STGO low-loaders).

In terms of weight distribution, we can confirm the following for a fully freighted trailer:

Standard 13.7m (8.1m wheelbase with 13m long load @ 28T): Kingpin Weight: 12,563kgs / Bogie weight: 22,936kgs

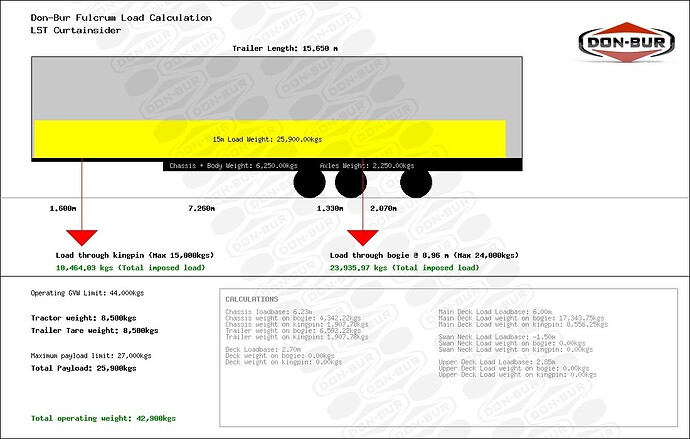

LST 15.650m (7.925m wheelbase to centre of tandem fixed bogie + 2.07m to rear self-steer axle with 15m long load @ 25.9T): Kingpin Weight: 10,464kgs / Bogie Weight: 23,995kgs EDITED

LST 15.650m (7.450m wheelbase to front fixed axle + 2 rear positive steer axles with 15m long load @ 27T): Kingpin Weight: 11,876kgs / Bogie Weight: 23,623kgs

It’s difficult to compare eggs with eggs here as the max payload weight differs with each solution.

We know that the low accident report rate coming from Risk Solutions Ltd on behalf of the DfT reflects carefully selected drivers who have had more training; particularly regarding swing-out at the rear. It is plausible that the RIDDOR accident rate might increase in line with 13.6/13.7m long trailers if LSTs became approved and released for general use.

We also know that, under the terms of the “Operator Undertaking” reports that go back to Risk solutions, every % fill and % weight capacity is recorded so productivity is measured relative to an operators “normal” load, whether that be heavy, dense loads or light, high volume loads.

We hope this helps.