Carryfast:

Trev_H:

Carryfast:

Wheel Nut:

Trev_H:

Carryfast:

Wheel Nut:

Postby Spardo » Fri Mar 17, 2006 12:58 am

Post by Dave the Renegade » Sat May 07, 2011 9:42 pm

This must be a record for a thread revival

But after all that no one seems to have remembered that shift pattern was what differentiated the typical lash up Brit cab over type remote linkage from the one used in conventionals in which it was the usual H pattern that applied.

It was nothing to do with the linkage ! they were 2 different boxes the “w” shift and the “H” shift. Incidentily if you put a gear stick direct (without linkage) into either of these boxes, the gears would be totally back to front.

Now I am doing it, apart from crawler the gearchange in my Fuller equipped ERF, Ford Transcontinental and Saviem were all the same way round as a Ford Cortina and Mini Cooper

The Leyland Marathon which I drove was H pattern too if I remember right with the 9 speed fuller in it and the T 45 was too but had the Spicer box not fuller

The Leyland Marathon which I drove was H pattern too if I remember right with the 9 speed fuller in it and the T 45 was too but had the Spicer box not fuller  but the difference between the Marathon and the W pattern used in the Fodens and Bedford TM’s was all in the linkage set ups not the boxes

but the difference between the Marathon and the W pattern used in the Fodens and Bedford TM’s was all in the linkage set ups not the boxes  Think it might even have been cable linkages on the Foden and Bedford but not the Marathon etc

Think it might even have been cable linkages on the Foden and Bedford but not the Marathon etc  .But the Magi Deutz conventional with a 9 speed Fuller was’nt a reverse H or reverse W it just had the brilliant shift quality of a direct linkage in an ordinary H pattern.

.But the Magi Deutz conventional with a 9 speed Fuller was’nt a reverse H or reverse W it just had the brilliant shift quality of a direct linkage in an ordinary H pattern.

So why did the W & H pattern boxes have different model numbers, if only the linkage was different?

It’s all a long time ago and I’m only going by memory and was never involved with building any trucks with fuller box installations.But I’d say that it would be a good guess that different part numbers on W type shift pattern boxes would have differentiated the 9 speed used with the cab over cable lash up type linkages and all the rest because it’s obvious that the cable operated types would need a different type of selector input at the box

.Although having said that it’s not all the Brits fault for using cab overs with that diabolical set up on the TM and Foden etc because Kenworth also used it on theirs apparently so it was probably a yank idea not ours

.Although having said that it’s not all the Brits fault for using cab overs with that diabolical set up on the TM and Foden etc because Kenworth also used it on theirs apparently so it was probably a yank idea not ours

.

.

Fuller’s own instructions from the time seem show that the difference between the H pattern boxes or W type was based on wether it was direct drive or the overdrive ( RTO type)  .

.

.

.

youtube.com/watch?v=5XxuM75a … re=related 2.36

youtube.com/watch?v=d9c2BTE_ … re=related

But seems to prove that I was right about clutchless shifts on fullers though. (nmm)

Carryfast:

Fuller’s own instructions from the time seem show that the difference between the H pattern boxes or W type was based on wether it was direct drive or the overdrive ( RTO type)  .

.

.

.

youtube.com/watch?v=5XxuM75a … re=related 2.36

youtube.com/watch?v=d9c2BTE_ … re=related

But seems to prove that I was right about clutchless shifts on fullers though. (nmm)

Carryfast, you didn’t mention clutchless shifting ! You’re insistance was that the difference between the W and H pattern boxes was down to the crap british installation, as usual you have been proved to be talking out your backside !

Doubt you’ve ever driven one let alone took one apart and overhauled it !

the 1979 foden 290 i had came with direct drive top gear , that was H pattern ., the firm installed an overdrive box which was W pattern , but the twin splitter was far superior to either imho , dave

Trev_H:

Carryfast:

Fuller’s own instructions from the time seem show that the difference between the H pattern boxes or W type was based on wether it was direct drive or the overdrive ( RTO type)  .

.

.

.

youtube.com/watch?v=5XxuM75a … re=related 2.36

youtube.com/watch?v=d9c2BTE_ … re=related

But seems to prove that I was right about clutchless shifts on fullers though. (nmm)

Carryfast, you didn’t mention clutchless shifting ! You’re insistance was that the difference between the W and H pattern boxes was down to the crap british installation, as usual you have been proved to be talking out your backside !

Doubt you’ve ever driven one let alone took one apart and overhauled it !

Blimey if you’d read the posts even I was questioning everything which I’d put down there from memory myself,without ever having seen the actual manufacturers notes in the day,just like most other Brit drivers because the internet had’nt been invented then

.

.

But drove enough 9 speeds to know the differences in using them just not the exact reasons for the shift pattern differences and the last time I drove a 9 speed fuller with that shift pattern was in a Foden gritter and that was as bad as I remember it in the TM and to add insult to injury the idiots had converted them from using the Foden box originially it’s just that it’s taken this long to find out that the shift pattern and diabolical shift quality were totally unrelated  .So it’s not surprising that without seeing that actual yank fuller info anyone who really ‘has’ driven them (here) could reasonably,mistakenly,confuse the differences being down to the different linkage set ups.But if you’re looking at it from a fitter’s point of view it’s not surprising that you’d have more chance of knowing the exact reasons for the differences better than a driver which is how the zb topic got on here in the first place.But notice that it took me to come up with the right definitive info to identify the exact differences,with the actual spec information,concerning the direct drive versions and the RTO versions,because I have’nt seen any other posts here which did that including yours.

.So it’s not surprising that without seeing that actual yank fuller info anyone who really ‘has’ driven them (here) could reasonably,mistakenly,confuse the differences being down to the different linkage set ups.But if you’re looking at it from a fitter’s point of view it’s not surprising that you’d have more chance of knowing the exact reasons for the differences better than a driver which is how the zb topic got on here in the first place.But notice that it took me to come up with the right definitive info to identify the exact differences,with the actual spec information,concerning the direct drive versions and the RTO versions,because I have’nt seen any other posts here which did that including yours.

But did’nt mention anything about clutchless shifting here but did on some other topics in arguments with newmercman so now maybe he can admit that he was wrong,based on fuller’s own info,just as I have.

Carryfast:

Trev_H:

Carryfast:

Fuller’s own instructions from the time seem show that the difference between the H pattern boxes or W type was based on wether it was direct drive or the overdrive ( RTO type)  .

.

.

.

youtube.com/watch?v=5XxuM75a … re=related 2.36

youtube.com/watch?v=d9c2BTE_ … re=related

But seems to prove that I was right about clutchless shifts on fullers though. (nmm)

Carryfast, you didn’t mention clutchless shifting ! You’re insistance was that the difference between the W and H pattern boxes was down to the crap british installation, as usual you have been proved to be talking out your backside !

Doubt you’ve ever driven one let alone took one apart and overhauled it !

Blimey if you’d read the posts even I was questioning everything which I’d put down there from memory myself,without ever having seen the actual manufacturers notes in the day,just like most other Brit drivers because the internet had’nt been invented then

.

.

But drove enough 9 speeds to know the differences in using them just not the exact reasons for the shift pattern differences and the last time I drove a 9 speed fuller with that shift pattern was in a Foden gritter and that was as bad as I remember it in the TM and to add insult to injury the idiots had converted them from using the Foden box originially it’s just that it’s taken this long to find out that the shift pattern and diabolical shift quality were totally unrelated  .So it’s not surprising that without seeing that actual yank fuller info anyone who really ‘has’ driven them (here) could reasonably,mistakenly,confuse the differences being down to the different linkage set ups.But if you’re looking at it from a fitter’s point of view it’s not surprising that you’d have more chance of knowing the exact reasons for the differences better than a driver which is how the zb topic got on here in the first place.But notice that it took me to come up with the right definitive info to identify the exact differences,with the actual spec information,concerning the direct drive versions and the RTO versions,because I have’nt seen any other posts here which did that including yours.

.So it’s not surprising that without seeing that actual yank fuller info anyone who really ‘has’ driven them (here) could reasonably,mistakenly,confuse the differences being down to the different linkage set ups.But if you’re looking at it from a fitter’s point of view it’s not surprising that you’d have more chance of knowing the exact reasons for the differences better than a driver which is how the zb topic got on here in the first place.But notice that it took me to come up with the right definitive info to identify the exact differences,with the actual spec information,concerning the direct drive versions and the RTO versions,because I have’nt seen any other posts here which did that including yours.

But did’nt mention anything about clutchless shifting here but did on some other topics in arguments with newmercman so now maybe he can admit that he was wrong,based on fuller’s own info,just as I have.

Ok then we’ll call that a draw then,

. The best fuller installation I’ve driven was in a normal control Leyland landtrain, this had a 290 ■■■■■■■ out front, the gearbox being under the cab the gearstick was direct into the top of the box. This gave a real slick shift but being direct meant that the H pattern was totally reversed, crawler being away from you and forward. Guys with a Gardner also had a neat shift with the W box fitted but top gear was right and forward on the inside of your left leg!

. The best fuller installation I’ve driven was in a normal control Leyland landtrain, this had a 290 ■■■■■■■ out front, the gearbox being under the cab the gearstick was direct into the top of the box. This gave a real slick shift but being direct meant that the H pattern was totally reversed, crawler being away from you and forward. Guys with a Gardner also had a neat shift with the W box fitted but top gear was right and forward on the inside of your left leg!

sammyopisite:

There was also the heavy haulage fuller box which was 15 speed and the layout was 5 over 5 and then a switch for the bottom 5 deep reduction and “Cambro’s” of Chesterfield had a 6x4 Atkinson with the 15 speed fuller and an auxiliary 4 speed box box giving it a possible 60 forward gears.

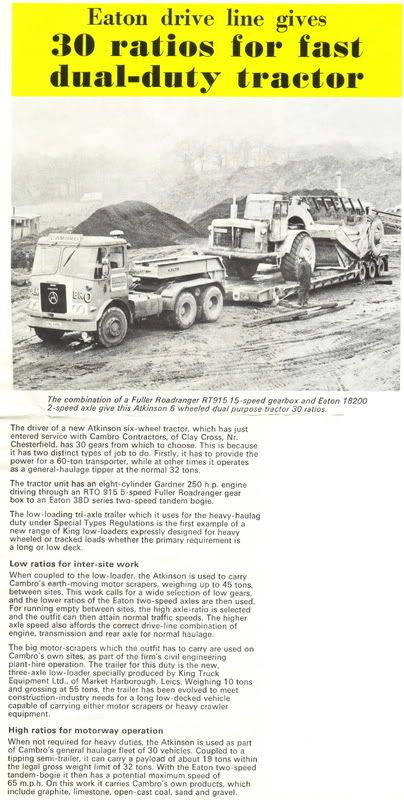

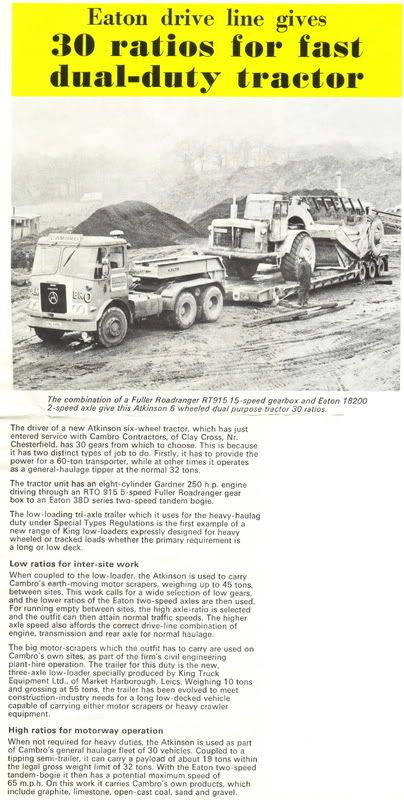

Are you sure about that, Johnnie? When it was new, it was described in the trade press as having a 15-speed Fuller and a pair of 2-speed axles, totalling 30 gears. It’s still around today, by the way.

240 Gardner:

sammyopisite:

There was also the heavy haulage fuller box which was 15 speed and the layout was 5 over 5 and then a switch for the bottom 5 deep reduction and “Cambro’s” of Chesterfield had a 6x4 Atkinson with the 15 speed fuller and an auxiliary 4 speed box box giving it a possible 60 forward gears.

Are you sure about that, Johnnie? When it was new, it was described in the trade press as having a 15-speed Fuller and a pair of 2-speed axles, totalling 30 gears. It’s still around today, by the way.

That’s what i understood the motor had the two speed rear axles.

Some lads will get the wrong idea talking about W’s and “carryfast” in the same post!!!

Trev_H:

Carryfast:

Wheel Nut:

Trev_H:

Carryfast:

Wheel Nut:

Postby Spardo » Fri Mar 17, 2006 12:58 am

Post by Dave the Renegade » Sat May 07, 2011 9:42 pm

This must be a record for a thread revival

But after all that no one seems to have remembered that shift pattern was what differentiated the typical lash up Brit cab over type remote linkage from the one used in conventionals in which it was the usual H pattern that applied.

It was nothing to do with the linkage ! they were 2 different boxes the “w” shift and the “H” shift. Incidentily if you put a gear stick direct (without linkage) into either of these boxes, the gears would be totally back to front.

Now I am doing it, apart from crawler the gearchange in my Fuller equipped ERF, Ford Transcontinental and Saviem were all the same way round as a Ford Cortina and Mini Cooper

The Leyland Marathon which I drove was H pattern too if I remember right with the 9 speed fuller in it and the T 45 was too but had the Spicer box not fuller

The Leyland Marathon which I drove was H pattern too if I remember right with the 9 speed fuller in it and the T 45 was too but had the Spicer box not fuller  but the difference between the Marathon and the W pattern used in the Fodens and Bedford TM’s was all in the linkage set ups not the boxes

but the difference between the Marathon and the W pattern used in the Fodens and Bedford TM’s was all in the linkage set ups not the boxes  Think it might even have been cable linkages on the Foden and Bedford but not the Marathon etc

Think it might even have been cable linkages on the Foden and Bedford but not the Marathon etc  .But the Magi Deutz conventional with a 9 speed Fuller was’nt a reverse H or reverse W it just had the brilliant shift quality of a direct linkage in an ordinary H pattern.

.But the Magi Deutz conventional with a 9 speed Fuller was’nt a reverse H or reverse W it just had the brilliant shift quality of a direct linkage in an ordinary H pattern.

So why did the W & H pattern boxes have different model numbers, if only the linkage was different?

I think there were 2 different Fuller boxes, we had both types fitted in the Scammell Crusaders at Sykes Bulk Liquids and it could be quite confusing when you had to swap motors. Along with the extra gear in high range crawler (W shift) you could get high reverse as well, which could be alarming if you started to reverse a bit quick!

Bewick:

Some lads will get the wrong idea talking about W’s and “carryfast” in the same post!!!

Ha ha sharp as ever nice 1

nah ,cant be bothered to argue , im soaking wet and dirty. jimbo

8LXBV8BRIAN:

240 Gardner:

sammyopisite:

There was also the heavy haulage fuller box which was 15 speed and the layout was 5 over 5 and then a switch for the bottom 5 deep reduction and “Cambro’s” of Chesterfield had a 6x4 Atkinson with the 15 speed fuller and an auxiliary 4 speed box box giving it a possible 60 forward gears.

Are you sure about that, Johnnie? When it was new, it was described in the trade press as having a 15-speed Fuller and a pair of 2-speed axles, totalling 30 gears. It’s still around today, by the way.

That’s what i understood the motor had the two speed rear axles.

Hi Chris and Brian you could be right as it was the driver who was telling me in the early 70s I was delivering either a scraper or a euclid to a new road site ( the A38 from the M1 to A61 stretch) and "Cambro’s Atki was delivering at the same time and I am sure I was driving the “Samson” as he was enquiring what gearbox it had then was telling me how he had a lot more gears ( why I don’t know as I never had to use the bottom 5 even when grossing over 90 tons ) it is probably down to the grain attacks on the brain as to me getting confused  but even at the time it did seem overkill. How would the 2 two speed axles work, would it be on similar lines to the “Foden” where you had to be stationary to change the diff ratio’s and only running either in low speed loaded and using high speed for light running or were they able to be used on the move the same as the eaton 2 speed axle.

but even at the time it did seem overkill. How would the 2 two speed axles work, would it be on similar lines to the “Foden” where you had to be stationary to change the diff ratio’s and only running either in low speed loaded and using high speed for light running or were they able to be used on the move the same as the eaton 2 speed axle.

cheers Johnnie

P S Steve , the 2 fuller boxes were the 10 speed behind the 220 Rolls and the 9 speed behind the 280 Rolls

It was a crash box and I struggled for the first hour as the plate showing the gears was worn out and what I discovered after much crucnching etc was…

No it wasn’t! It was a Constant Mesh box, true some Constant Mesh boxes had crash gears on Crawler or Reverse (hence the crunch at times) but you would only be moving very slowly into or out of Crawler. The noises you made during changes up and down the box were due to poor changing techniques not the gearbox. It would be impossible to use a Crash Gearbox with Nine gears at the speeds vehicles ran at in the Sixties never mind later and with the weights they pulled. Basically if you drove an HGV after the Sixties (and mostly before this time) then you never drove a true Crash Box, they were all Constant Mesh until the Syncromesh types plus the Semi and Automatics you could also come across. if you want ot know the difference between Crash and Constant Mesh, its all in the way the gears are made and meshed. Crash boxes straight cut teeth (noisy) and separate gears moved into mesh when selecting the next gear (even noisier), now we are talking about motors that would be around during the 20mph speed limit 1800’s to 1920/30’s. Constant Mesh boxes have gears cut at an angle and as the name says are in constant mesh (much quieter) and they use dog clutches (smaller gears that slip into the centre of the bigger meshed gears when gear selecting (should be quiet too but poor changing meant tunes from the dog clutches) hence drivers presumed wrongly they were driving a crash box. Happily along came the Synchromesh and everything was even more quieter and easier to engage (unless of course you double de clutched as I’ve known some drivers to do, oh oh). Of course the Crash Box and the Constant Mesh needed the double de clutch technique but good CM boxes allowed silent changes without the clutch, as you were engaging the Dogs at the right engine and shaft speed, you couldn’t do that with a real Crash Box unless the clutch was depressed. Sorry to go on but I think this needed explaining, although very basically, as I’ve seen this written and said so many times. Sorry also if I’ve dented your pride now you realise you didn’t really drive a crash gearbox in your 38 tonne ERF built in 1980, all you did was beat the box up a bit! Cheers Franky.

Frankydobo:

It was a crash box and I struggled for the first hour as the plate showing the gears was worn out and what I discovered after much crucnching etc was…

No it wasn’t! It was a Constant Mesh box, true some Constant Mesh boxes had crash gears on Crawler or Reverse (hence the crunch at times) but you would only be moving very slowly into or out of Crawler. The noises you made during changes up and down the box were due to poor changing techniques not the gearbox. It would be impossible to use a Crash Gearbox with Nine gears at the speeds vehicles ran at in the Sixties never mind later and with the weights they pulled. Basically if you drove an HGV after the Sixties (and mostly before this time) then you never drove a true Crash Box, they were all Constant Mesh until the Syncromesh types plus the Semi and Automatics you could also come across. if you want ot know the difference between Crash and Constant Mesh, its all in the way the gears are made and meshed. Crash boxes straight cut teeth (noisy) and separate gears moved into mesh when selecting the next gear (even noisier), now we are talking about motors that would be around during the 20mph speed limit 1800’s to 1920/30’s. Constant Mesh boxes have gears cut at an angle and as the name says are in constant mesh (much quieter) and they use dog clutches (smaller gears that slip into the centre of the bigger meshed gears when gear selecting (should be quiet too but poor changing meant tunes from the dog clutches) hence drivers presumed wrongly they were driving a crash box. Happily along came the Synchromesh and everything was even more quieter and easier to engage (unless of course you double de clutched as I’ve known some drivers to do, oh oh). Of course the Crash Box and the Constant Mesh needed the double de clutch technique but good CM boxes allowed silent changes without the clutch, as you were engaging the Dogs at the right engine and shaft speed, you couldn’t do that with a real Crash Box unless the clutch was depressed. Sorry to go on but I think this needed explaining, although very basically, as I’ve seen this written and said so many times. Sorry also if I’ve dented your pride now you realise you didn’t really drive a crash gearbox in your 38 tonne ERF built in 1980, all you did was beat the box up a bit! Cheers Franky.

We knew it as the ’ crack’em and smack’em box’ - brute force applied deftly was all you needed!

stevecook:

Frankydobo:

It was a crash box and I struggled for the first hour as the plate showing the gears was worn out and what I discovered after much crucnching etc was…

No it wasn’t! It was a Constant Mesh box, true some Constant Mesh boxes had crash gears on Crawler or Reverse (hence the crunch at times) but you would only be moving very slowly into or out of Crawler. The noises you made during changes up and down the box were due to poor changing techniques not the gearbox. It would be impossible to use a Crash Gearbox with Nine gears at the speeds vehicles ran at in the Sixties never mind later and with the weights they pulled. Basically if you drove an HGV after the Sixties (and mostly before this time) then you never drove a true Crash Box, they were all Constant Mesh until the Syncromesh types plus the Semi and Automatics you could also come across. if you want ot know the difference between Crash and Constant Mesh, its all in the way the gears are made and meshed. Crash boxes straight cut teeth (noisy) and separate gears moved into mesh when selecting the next gear (even noisier), now we are talking about motors that would be around during the 20mph speed limit 1800’s to 1920/30’s. Constant Mesh boxes have gears cut at an angle and as the name says are in constant mesh (much quieter) and they use dog clutches (smaller gears that slip into the centre of the bigger meshed gears when gear selecting (should be quiet too but poor changing meant tunes from the dog clutches) hence drivers presumed wrongly they were driving a crash box. Happily along came the Synchromesh and everything was even more quieter and easier to engage (unless of course you double de clutched as I’ve known some drivers to do, oh oh). Of course the Crash Box and the Constant Mesh needed the double de clutch technique but good CM boxes allowed silent changes without the clutch, as you were engaging the Dogs at the right engine and shaft speed, you couldn’t do that with a real Crash Box unless the clutch was depressed. Sorry to go on but I think this needed explaining, although very basically, as I’ve seen this written and said so many times. Sorry also if I’ve dented your pride now you realise you didn’t really drive a crash gearbox in your 38 tonne ERF built in 1980, all you did was beat the box up a bit! Cheers Franky.

We knew it as the ’ crack’em and smack’em box’ - brute force applied deftly was all you needed!

The correct term is sliding mesh and they need exactly the same skills to drive them as constant mesh.This bloke obviously does’nt have them.

youtube.com/watch?v=UoqPFKnB … re=related

240 Gardner:

8LXBV8BRIAN:

240 Gardner:

sammyopisite:

There was also the heavy haulage fuller box which was 15 speed and the layout was 5 over 5 and then a switch for the bottom 5 deep reduction and “Cambro’s” of Chesterfield had a 6x4 Atkinson with the 15 speed fuller and an auxiliary 4 speed box box giving it a possible 60 forward gears.

Are you sure about that, Johnnie? When it was new, it was described in the trade press as having a 15-speed Fuller and a pair of 2-speed axles, totalling 30 gears. It’s still around today, by the way.

That’s what i understood the motor had the two speed rear axles.

Hi Chris thanks for putting the correct information on as wrong seems to be what I excel at  but it was around 40 years ago and the brain is corroded now and that also explains to why they had the two speed axle as it was not necessary on heavy work only with the 15 speed fuller which had more than enough gears to do what was required of it.

but it was around 40 years ago and the brain is corroded now and that also explains to why they had the two speed axle as it was not necessary on heavy work only with the 15 speed fuller which had more than enough gears to do what was required of it.

cheers Johnnie

Although not quite in the Heavy Hauler league this Atki Borderer we ran was fairly unique as it had a ■■■■■■■ 220, Fuller 610 and Eaton 2 speed axle.It was delivered new at the end of '72 and was our 3rd new Atki.the one before it also had an Eaton axle,but single speed and a top speed of circa 57/8 mph.So I thought lets see if we could “gear up” the 3rd one! We stuck the two speed shift straight onto the existing axle ratio,oh dear oh dear!!! You had to be doing over 70mph to change up into top(20th)!!! It was so high geared. So we had to change the crown wheel and pinion for a lower ratio which was then spot on! The Atki would still do 70 in top this time but it also pulled like a train with having 20 gears to go at! I’m not kidding when I say it could “urinate” all over 8LXB’s and 240 F88’s at the time as it was far better geared than them.However it did need a decent driver(which it had) to be able to make it perform to the best of it’s abilit y.Cheers Dennis.

y.Cheers Dennis.

Bewick:

Although not quite in the Heavy Hauler league this Atki Borderer we ran was fairly unique as it had a ■■■■■■■ 220, Fuller 610 and Eaton 2 speed axle.It was delivered new at the end of '72 and was our 3rd new Atki.the one before it also had an Eaton axle,but single speed and a top speed of circa 57/8 mph.So I thought lets see if we could “gear up” the 3rd one! We stuck the two speed shift straight onto the existing axle ratio,oh dear oh dear!!! You had to be doing over 70mph to change up into top(20th)!!! It was so high geared. So we had to change the crown wheel and pinion for a lower ratio which was then spot on! The Atki would still do 70 in top this time but it also pulled like a train with having 20 gears to go at! I’m not kidding when I say it could “urinate” all over 8LXB’s and 240 F88’s at the time as it was far better geared than them.However it did need a decent driver(which it had) to be able to make it perform to the best of it’s abilit y.Cheers Dennis.

y.Cheers Dennis.

A load of ■■■■■■■■ Cowboys

Dave the Renegade:

Bewick:

Although not quite in the Heavy Hauler league this Atki Borderer we ran was fairly unique as it had a ■■■■■■■ 220, Fuller 610 and Eaton 2 speed axle.It was delivered new at the end of '72 and was our 3rd new Atki.the one before it also had an Eaton axle,but single speed and a top speed of circa 57/8 mph.So I thought lets see if we could “gear up” the 3rd one! We stuck the two speed shift straight onto the existing axle ratio,oh dear oh dear!!! You had to be doing over 70mph to change up into top(20th)!!! It was so high geared. So we had to change the crown wheel and pinion for a lower ratio which was then spot on! The Atki would still do 70 in top this time but it also pulled like a train with having 20 gears to go at! I’m not kidding when I say it could “urinate” all over 8LXB’s and 240 F88’s at the time as it was far better geared than them.However it did need a decent driver(which it had) to be able to make it perform to the best of it’s abilit y.Cheers Dennis.

y.Cheers Dennis.

A load of ■■■■■■■■ Cowboys

Too many gears for you my son!!! The 4 in the TK was about what you’d be able to manage!!!For the first 18 months this Atki was doing 3 round trips to the London area then we sent it to Daventry when we started our night trunks where it ran to West Thurrock and then re-loaded at Tilbury with woodpulp for Beetham.

The Leyland Marathon which I drove was H pattern too if I remember right with the 9 speed fuller in it and the T 45 was too but had the Spicer box not fuller

but the difference between the Marathon and the W pattern used in the Fodens and Bedford TM’s was all in the linkage set ups not the boxes

Think it might even have been cable linkages on the Foden and Bedford but not the Marathon etc

.But the Magi Deutz conventional with a 9 speed Fuller was’nt a reverse H or reverse W it just had the brilliant shift quality of a direct linkage in an ordinary H pattern.

.Although having said that it’s not all the Brits fault for using cab overs with that diabolical set up on the TM and Foden etc because Kenworth also used it on theirs apparently so it was probably a yank idea not ours

.

![]() .

. ![]()

![]()

![]() .

.![]()

y.Cheers Dennis.

y.Cheers Dennis.