driver travelled 300 miles without trailer being connected properly,I doubt it what do you think ?

![]() It does sound odd. Drive all day then 300 miles later the trailer breaks free.

It does sound odd. Drive all day then 300 miles later the trailer breaks free.

blod65:

driver travelled 300 miles without trailer being connected properly,I doubt it what do you think ?Staffordshire Live - Latest local news, sport & business from Staffordshire

Sounds like he was unbelievably unlucky if he’d got that far without it letting go if it was’nt coupled up right.But the old back under the trailer and then pull forward to check it’s coupled up is’nt always enough.It can be possible for that not to always be a guarantee.It can also be a case that the fifth wheel handle will go back far enough to put the safety chain on too without the jaws being fully home round the king pin.The best way is to couple up pull forward and then get under to have a look at the fifth wheel jaws to make sure that the pin is covered.But one of the causes of mis coupling is landing legs being wound right down when trailers are dropped and/or too much height.It’s best to make sure that the trailer is at a low enough level relative to the unit height so the unit lifts the trailer off it’s landing legs and it sits on the turntable properly before the jaws lock on the pin.

blod65:

driver travelled 300 miles without trailer being connected properly,I doubt it what do you think ?Staffordshire Live - Latest local news, sport & business from Staffordshire

Must admit when I read it in Sentinel yesterday there was just something a bit unbelievable about it. Not sure where he went but I dare say he went over a pothole or two and maybe even a speed bump.

300 k maybe not 300 miles

you would have thought braking would have force the pin into jaws

but whats done is done

hopefully no one hurt when it dropped off

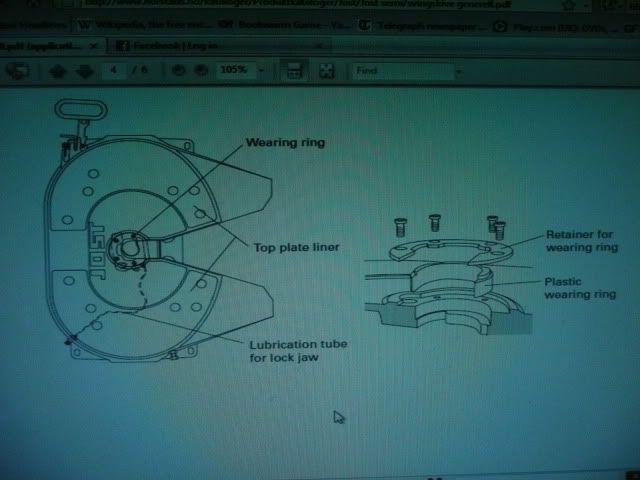

They did discover a fault on the plastic wearing ring on one of our trucks. The driver picked a trailer up in Poole Harbour, drove it back 300km to Hilton and it came off in the yard ![]()

It is a simple check when the unit is uncoupled, just look at the throat for cracks on the white insert, 2 minute fix.

damage is accentuated when driving on and off ferry ramps at stupid angles

Wheel Nut:

They did discover a fault on the plastic wearing ring on one of our trucks. The driver picked a trailer up in Poole Harbour, drove it back 300km to Hilton and it came off in the yardIt is a simple check when the unit is uncoupled, just look at the throat for cracks on the white insert, 2 minute fix.

damage is accentuated when driving on and off ferry ramps at stupid angles

Blimey so effectively all that stands between an artic staying coupled up and the trailer flying off the back of the unit is a piece of plastic.As if we have’nt got enough problems.

Carryfast:

Wheel Nut:

They did discover a fault on the plastic wearing ring on one of our trucks. The driver picked a trailer up in Poole Harbour, drove it back 300km to Hilton and it came off in the yardIt is a simple check when the unit is uncoupled, just look at the throat for cracks on the white insert, 2 minute fix.

damage is accentuated when driving on and off ferry ramps at stupid angles

Blimey so effectively all that stands between an artic staying coupled up and the trailer flying off the back of the unit is a piece of plastic.As if we have’nt got enough problems.

The picture is a bit poor as I took it from my screen, but that is about the size of it ![]()

iF he did his 2 shunts forward and the safety clip was in place he has done all he can as a driver he is not a mechanic.

Was the safety clip in place ■■?

Wheel Nut:

Carryfast:

Wheel Nut:

They did discover a fault on the plastic wearing ring on one of our trucks. The driver picked a trailer up in Poole Harbour, drove it back 300km to Hilton and it came off in the yardIt is a simple check when the unit is uncoupled, just look at the throat for cracks on the white insert, 2 minute fix.

damage is accentuated when driving on and off ferry ramps at stupid angles

Blimey so effectively all that stands between an artic staying coupled up and the trailer flying off the back of the unit is a piece of plastic.As if we have’nt got enough problems.

The picture is a bit poor as I took it from my screen, but that is about the size of it

Thanks for that education as they say it does’nt matter how long you’ve been there there’s always something new to learn.I’ve always thought that the problems are behind the pin when you’ve coupled up.Having said that I can remember feeling a slight amount of forward and rearward slop in some artic outfits and not others never thought anything of it ,(until now).Yet another reason why I prefer wagon and drags but can’t use those on traction work unfortunately.But at least I’ve been lucky enough to find out before losing any trailers.

some dodgy company mechanics when they get that slight amount of forward and rearward slop get an empty coke can ( many other types could be used ) cut of the top and bottom and cut out a 3 inch slit in the side and place that in as a spacer …to get the truck thro the MOT …When all they had to to was tigten up a bolt ( normally seized tho ) So they use the can option. When the truck has passed the MOT the can disintergrates within 1-2 days and the slop is back.

They need the sack and locking up…

So when a driver reports a defect they should get it signed and keep a copy for themself …

26 years an Lgv Trainer:

some dodgy company mechanics when they get that slight amount of forward and rearward slop get an empty coke can ( many other types could be used ) cut of the top and bottom and cut out a 3 inch slit in the side and place that in as a spacer …to get the truck thro the MOT …When all they had to to was tigten up a bolt ( normally seized tho ) So they use the can option. When the truck has passed the MOT the can disintergrates within 1-2 days and the slop is back.They need the sack and locking up…

So when a driver reports a defect they should get it signed and keep a copy for themself …

Or like us drivers maybe the fitters have got some tight fisted guvnor over them who won’t spend the money on the time required and also the parts to let them fit a new plastic wear ring,new retainer,and all new bolts on a regular preventative basis?.

Carryfast:

26 years an Lgv Trainer:

some dodgy company mechanics when they get that slight amount of forward and rearward slop get an empty coke can ( many other types could be used ) cut of the top and bottom and cut out a 3 inch slit in the side and place that in as a spacer …to get the truck thro the MOT …When all they had to to was tigten up a bolt ( normally seized tho ) So they use the can option. When the truck has passed the MOT the can disintergrates within 1-2 days and the slop is back.They need the sack and locking up…

So when a driver reports a defect they should get it signed and keep a copy for themself …

Or like us drivers maybe the fitters have got some tight fisted guvnor over them who won’t spend the money on the time required and also the parts to let them fit a new plastic wear ring,new retainer,and all new bolts on a regular preventative basis?.

Hence >>>>> when a driver reports a defect they should get it signed and keep a copy for themself … So If something like this happens you have got proof of defects reported ,

26 years an Lgv Trainer:

Carryfast:

26 years an Lgv Trainer:

some dodgy company mechanics when they get that slight amount of forward and rearward slop get an empty coke can ( many other types could be used ) cut of the top and bottom and cut out a 3 inch slit in the side and place that in as a spacer …to get the truck thro the MOT …When all they had to to was tigten up a bolt ( normally seized tho ) So they use the can option. When the truck has passed the MOT the can disintergrates within 1-2 days and the slop is back.They need the sack and locking up…

So when a driver reports a defect they should get it signed and keep a copy for themself …

Or like us drivers maybe the fitters have got some tight fisted guvnor over them who won’t spend the money on the time required and also the parts to let them fit a new plastic wear ring,new retainer,and all new bolts on a regular preventative basis?.

Hence >>>>> when a driver reports a defect they should get it signed and keep a copy for themself … So If something like this happens you have got proof of defects reported ,

This site should be compulsory reading for all drivers.It could save us all a lot of problems.But how many drivers know and are taught when we learn to drive artics,including me,that if you ever detect that type of slight movement between unit and trailer then get it in the book and don’t use the wagon until it’s been fixed?.But I can remember our defect book as only having two copies? one was left in the book the other was kept by the workshops and both were signed by the fitter when he’d rectified the fault?.At least I won’t have those issues if I’m an owner driver in future because it will all be down to me to make sure the job’s done properly.

26 years an Lgv Trainer:

iF he did his 2 shunts forward and the safety clip was in place he has done all he can as a driver he is not a mechanic.

Rubbish. It takes less than 10 seconds to get under the trailer and shine a torch at the jaws to check they’re shut. ![]()

I don’t think Ive ever noticed this plastic wearing ring , I’ll have to have a look on monday.

This forward and rearward slop(i call it trailer slapping) you are talking off could this be a cause of the plastic wearing ring? As Ive encountered this movement but i thought as long as the jaws are shut - the trailer is going no-where.

I get under the trailer with a torch and check the jaws, i never used to do this but a agency fella told me a horror story so i check the jaws all the time now. It really should be a compulsory check but most folk don’t do it, well the ones i see anyway.

merc0447:

I don’t think Ive ever noticed this plastic wearing ring , I’ll have to have a look on monday.This forward and rearward slop(i call it trailer slapping) you are talking off could this be a cause of the plastic wearing ring? As Ive encountered this movement but i thought as long as the jaws are shut - the trailer is going no-where.

I get under the trailer with a torch and check the jaws, i never used to do this but a agency fella told me a horror story so i check the jaws all the time now. It really should be a compulsory check but most folk don’t do it, well the ones i see anyway.

Getting under and checking the jaws of the fifth wheel is something the old drivers told me years ago from when I started out but as it’s been shown here the trailer probably might even then still be ‘going somewhere’ if it’s shifting around in the coupling because there’s too much clearance caused by a worn out plastic wearing ring?.As wheelnut said he’s seen a trailer that ran for 300 km’s sitting happily on the back of the unit all the way and then it fell off without being uncoupled in the yard.Nuf said.It probably comes under the road traffic act the driver is responsible for the condition and security of the vehicle and anything attatched to it.But it’s taken some education on here for some of us including me to learn something I never knew before.

I get under the trailer with a torch and check the jaws, i never used to do this but a agency fella told me a horror story so i check the jaws all the time now. It really should be a compulsory check but most folk don’t do it, well the ones i see anyway.

[/quote]

Some of our guys will never do this, as they can’t even be bothered to give the coupling a couple of tugs or use the dogclip! Like several others on here, I always check with a torch to see if the jaws have closed and I always show new artic drivers the “right” way, but I never see them checking with a torch though. ![]()

If drivers used the correct un-coupling and coupling procedures rather than reverse up, couple (regardless of the height of the trailer plate in relation to the fifth wheel) and drive away.I see this day in day out, very few drivers making use of the air suspension most trucks have fitted nowadays-its there to for a reason and not just to level up at the loading dock!.

JUST BECAUSE THE CLIP CAN BE INSERTED DOES NOT MEAN THE TRAILER IS COUPLED CORRECTLY,the pin could be sat on top of the jaws,enough to do the ‘tug test’ resulting in the driver thinking the trailer is safely coupled,this will nearly always happen if the trailer is fully loaded,then as the driver does his/hers deliveries the weight comes off the trailer allowing the trailer pin to lift/move over the jaws of the fifth wheel with disastrous results.

mick palmer:

If drivers used the correct un-coupling and coupling procedures rather than reverse up, couple (regardless of the height of the trailer plate in relation to the fifth wheel) and drive away.I see this day in day out, very few drivers making use of the air suspension most trucks have fitted nowadays-its there to for a reason and not just to level up at the loading dock!.

JUST BECAUSE THE CLIP CAN BE INSERTED DOES NOT MEAN THE TRAILER IS COUPLED CORRECTLY,the pin could be sat on top of the jaws,enough to do the ‘tug test’ resulting in the driver thinking the trailer is safely coupled,this will nearly always happen if the trailer is fully loaded,then as the driver does his/hers deliveries the weight comes off the trailer allowing the trailer pin to lift/move over the jaws of the fifth wheel with disastrous results.

I use the air suspension to couple up (on the rare times when I have to) then raise it up when Im near the pin ![]()

I have overshot the pin a few times and got it jamed between the fifth wheel and the cab and the air suspension got me out of a sticky situation - that said it was a MAN TGA ![]()

![]()

![]()

![]()