I also found this photo of my Scimitar coup , there’s a story to tell ? Working at S Jones I became quite good at fibre glass repairs to crashed cabs etc . The Scimitar was made up of the same material as the ERFs .The original car was to tight in the back as the kids where growing up , So I extended the back end to accordingly so the kids had more room ? I cut the roof across in the middle just rear of the door ,and along the sides removing the boot lid, I slid the roof back ? I put the boot lid on the roof to bridge the gap The top overhung the sides As the back tapered in ? Then I removed the rear window and cut the roof in half to get the top to sit along the open boot area now with the roof overlapping the window could not be fitted ? So I recut the rear window so that it could now be fitted all this was fibre glassed and new widows fitted in the sides , I moulded the rear end with 1/2 a brake shoe the finished car was that good , people used to ask me what is your car , ? On the back I had in bold letters RSS 1 I purchased the part worn tyres from Edward Jones Aston Martin volanti and drove this car for years with bags of sand in the back to keep it on the road in icy weather Ron

ronhawk:

ergomatic man:

hi there is that marline who run pittssteel just down the rd from s jones in middlemore lane.Ergomatic man !! Yes that’s was Marline she was a cracker , she came round to our house when I first started working for her , in her Jag , , She had on a fur coat and my daughter kept pulling the fur? it could well have been genuine mink ? Or may be rabbet ! She opened up her own steel stockholders in Aldridge and later her warehouse Swallow steel in Hensford she used to tell me where I was to deliver steel to giving me the instructions sitting at her desk , I was standing over her !!! Then she would say ? (Have you got that Ron ) she always had on low cut tops ,!! I said can you run through that again Marline . I did not quite understand what you said !!! I worked there for 2 -3 years ! any one carrying Picked & Oiled steel plate , they will tell you it’s slippery stuff , amongst a variety of all steel beams , plate , etc, Ron

did you work for pitts or just swallowhill you may no my dad tony mason and his brother colin they was at pitts till it finished,there was another chap from pitts who went onto swallowhill named alan wilkes he used to drive the leyland constructor and used to park in burnfields close off leighswood rd.

The answer is don’t know ! This was at Aldridge stock holders Midlemore lane There was Erick on the 4 wheeler Brian in the warehouse and me on the artic then they all moved to Swallow , Ron

ronhawk:

The answer is don’t know ! This was at Aldridge stock holders Midlemore lane There was Erick on the 4 wheeler Brian in the warehouse and me on the artic then they all moved to Swallow , Ron

those names ring a bell my dad would have known them did aldridge stockholders used to run a bison at sometime?i used to drive for barclay mathieson brownhills and couple of lads there used to work for marlene micky dumbleton &bob carley is brother don used to drive for s jones on the tanks don carley.Tony

The best about putting memories down on this thread is that it brings back stories from yesterday’s The men and drivers that I have known , mainly associated with S Jones and Trans Arabia will live on, The tyre tracks that have been left in the deserts of Saudi Arabia and back at home , Time will overtake them , but can’t wipe them out , Thanks to Mirlin for his thread ,all the Brits that I have worked with and met along this long road where brilliant , Just hard working blokes , Ron

ronhawk:

The best about putting memories down on this thread is that it brings back stories from yesterday’s The men and drivers that I have known , mainly associated with S Jones and Trans Arabia will live on, The tyre tracks that have been left in the deserts of Saudi Arabia and back at home , Time will overtake them , but can’t wipe them out , Thanks to Mirlin for his thread ,all the Brits that I have worked with and met along this long road where brilliant , Just hard working blokes , Ron

Yes Ron, great thread with memories for me because it was our time. Even while I was there, 1976 to 1987, the changes were unbelievable. Particularly in Riyadh. As said before, in 1979, we were delivering hundreds and hundreds of container loads of Irish Peat Moss (few environmentalists then!) to a company in Riyadh whose name will come back to me about 5am tomorrow, their depot was miles away in the desert.

In 1986, Mosvold Furniture, who rented our Dammam warehouse, invited Julie and me to a party at their villa in Riyadh. By then I was general manager at Caravan - dead men’s shoes. We drove to Riyadh on the new dual carriageway - so much safer than the old single track, with Pat and Pauline Conway. It was great to count the Caravan trucks going both ways, ERFs and Scanias.

By then the airport, which had been on the very edge of town, had been absorbed into the city and a new one built. When we got to the Mosvold villa, which was miles into town. I realised that it was very near to where we used to unload the peat moss in the desert ten years before!

Julie reminded me that she had travelled home Saudia (we did their airfreight,and got massive ticket reductions) alone, via Riyadh’s new state of the art airport and got lost in the terminal. A soldier, who wouldn’t look at, or talk to her led her back from where she was to the main terminal. She went in the loos, but they were ‘squats’ and full of s***, despite being brand new. By the time she got on the plane she was close to wetting herself!

Happy days!

John

The revolution has started Saudi Oil Taps will eventually be turned down to a trickle ,Maybe not in my live time . Exhaust emissions its reported is the cause of nearly 1/2 a million deaths in Europe a year . I remember the smog in winter , when growing up as a kid ,it was that bad you could pass your own gate in the street when walking along the pavement , and I vividly remember taking a short cut across a field in thick smog only to arrive at the gate that I started at !! I was compleatly disordernated I must have been in that field for ages ? Every body had coal fires , The bus depo was nearby and the fleet was mainly 5.pot Gardner’s blowing smoke rings as they warmed up , the factory Furness belching out clouds of smoke this was 1940s the German bombers dropping bombs on us bloody hell how did we survive . Then working as a mechanic in the 50s on the Gardner’s engines they where that thick with black carbon deposits you could not see the valve springs or head bolts. Then the oil changed to Detergent and new filters where fitted the deference was marvellous the engines became bigger 6lx 8lxb and cleaner , the garage had exhaust pipes hanging down to take away the fumes . So called Modern engines where developed . A variety of HGVs where tested at S Jones , the one that gave least problems was the ERF powered by ■■■■■■■ , this was the truck we had in Saudi and it was good , up against the Detroit Diesel, The Mack , Cat, etc , the ■■■■■■■ was the heart of a good truck , I was proud to be involved with this truck for 6 1/2 years and knew every skill not only to drive but to keep them runnings in the heat of KSA, Ron

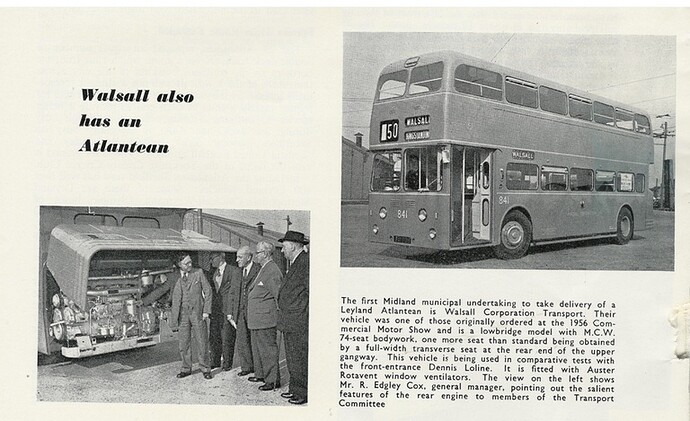

An’t it marvellous Walsall where one of the last councils to run Trolly buses , and they where quick and I mean Quick. The only trouble was the overhead power lines, the acceleration could throw you back if the driver put his foot down ? also the deceleration was good too , with the electric battery,s of today ,the cars of tomorrow are being built and must be fantastic , I have written before about Mr Cox he was the GM of the Walsall Bus Corporation and one day it must have been round about 1952 we all where called out of the workshops to sit on a trolly bus in the yard , this was an experiment!! The lower deck of the bus was covered in batteries, we sat down upstairs and lit up !!! The trolly bus went round the yard under battery power , this stuck with me and I to developed a battery powered M/ bike for the year 2000 this was brilliant but heavy and short on travel about 12miles, it’s now partly dismantled in the shed !! This could be resurrected with lighter batteries Ron

For all the old Gardner fitters !! I’ve just cleaned up a couple of spanners that I used on that remarkable engine that will stand the test of time . The first time was at Walsall Bus dep as an apprentice under Herbert Wolf 1951 mainly on 5lw last time I used these where at , S Jones 6lx - 8LXB and then Sam Satterwhait Foden garage Chester Rd Streetly in the 90s , Ron

ronhawk:

An’t it marvellous Walsall where one of the last councils to run Trolly buses , and they where quick and I mean Quick. The only trouble was the overhead power lines, the acceleration could throw you back if the driver put his foot down ? also the deceleration was good too , with the electric battery,s of today ,the cars of tomorrow are being built and must be fantastic , I have written before about Mr Cox he was the GM of the Walsall Bus Corporation and one day it must have been round about 1952 we all where called out of the workshops to sit on a trolly bus in the yard , this was an experiment!! The lower deck of the bus was covered in batteries, we sat down upstairs and lit up !!! The trolly bus went round the yard under battery power , this stuck with me and I to developed a battery powered M/ bike for the year 2000 this was brilliant but heavy and short on travel about 12miles, it’s now partly dismantled in the shed !! This could be resurrected with lighter batteries Ron

looks like harden road shops turning into walker road

ANOTHER TIME BUT THE SAME PLACE Nice one Curnock , the photo below is in Bloxwich and that’s my mates Albert Mintons Metropolitan, We went to Doncaster in that car , Ron

This is a photo of the tower truck used for repairs to the Trolly bus over head power lines , when working at the bus depo as a young lad a mate of mine Ronny Hodson he was on the overhead line crew , one night it was tipping down with rain and they where called out for a repair on Bloxwich rd ? He was on top of the Tower and by mistake grabbed hold of both lines !!! The electric shock made him Bite through his tongue it was just hanging on and went to the hospital ! his tongue was stitched back on, he was in trouble for quite some time but was OK , Ron

HOW TO TURN FOUR WEEKS INTO 48Hs Working on the Gardner engines at the Bus Depo in Leamore we had ample time to completely overhaul the 5 lw’s !!! I think ? Maybe 4weeks , I know that seams a long time ! But after stripping down the engine the cast iron crank case was in a bath of boiling Tricoethylene for 2days to clean out the black carbon that had built up inside especially round the cam shaft nooks and crannies , then it was hosed down ? And then only if Herbert Wolf said OK ? could i take it back to the cradle , The crank case was fitted out with White metal main bearings , this is where the skill came in !! The line boar was was set up and the cutting tool moved along turning out ribands of pure White metal, this took time to get (close) to the outer diameter of the crank Shaft using micrometers and then hand scraping of the bearings took place with engineers Blue until near perfection was obtained ,what a place to learn all skills ,this was just the bottom end ,The engines that came out where fantastic ,Then the 6 lw started to Arrive the main bearings where pre set no boring reg making the job easy’er but still built with pride ,from top to bottom calibration included ,What a difference from the modern engines today , Woking for GCC in Dammam we turned out ■■■■■■■ engine rebuild ,in some cases 48hrs for the oil fields in KSA , that including 8hr on the Dyno (we where flat out ) in 40deg Ron ![]()

The Walsall Bus Depo , deserves a paragraph on this thread !! When the buses became due for a compleat overhaul they parked up at the docking bay there where 2 long pits and two teems of mechanics completely stripping out all parts of the Guy Buses every part went to a section to be renewed , engines wheeled to our workshop just across the road on heavy trolleys gearboxes to there section etc etc ,absolutely every component , brakes drums, axel , steering box , brake (vacuum cylinder ) seating recovered with rexene , when completed all put back together . Our engine trolled back to be fitted . This was the best part !! the finished Bus was left out side our workshop to be tested by ourselves , we added a pint of running in solution to the oil and left it on just above tick over for 1/2 a day adjusting oil pressure Tappets etc then we road tested the Bus which was like new out on the rd , with Herbert Wolf driving , The satisfaction I felt on all rebuilds was brilliant, and still to this day,! even if it’s just fitting a cam belt and starting up the family’s cars Its job satisfaction Ron

Hi Ron,

Great tales of proper fitting.

Out of curiosity, did you ever come across any Midland Red buses, D9 I think they were. I think they had an engine designed by themselves.

Done a little time for a company running obsolete buses, anyway, we had one of these, had accumalator brakes driven off the prop behind the gearbox.

No reservoir filled with nitrogen like the London RM buses.

Bloody lethal at slow speeds, had to stand up on the pedal and try and bend the steering wheel to stop them when moving them around the garage.

Used to scare me silly.

Well thank you AV 760, I do tend to write about how it was in my life time ! The chapters of change that I have been involved with in transport to me is I hope something that keeps me sharp in my old age . But I must confess I never knew of the Midland Red D9 or there braking system on a PSV seems from the write up something that I to would be scared off , When I came back to the Walsall Depo after serving in the British Army , I worked in the gearbox section and we overhauled , G/boxes ,Diffs , steering box , and the braking system! The vacuum servo was about 8 inch Aloy cylinder with a leather sealed piston softened with engine oil and a complicated arrangement of leavers which operated an air valve housed in a brass box not much bigger than a a match box this had a double brass piston with rubber valves seated at each end ,when the brakes where applied the vacuum assisted master cylinder put on the brakes I always thought this was a bit suspect but when set up they where adequate the brakes where in my opinion well cared for at Walsall, and not to many hills off consequent , Ron

ronhawk:

HOW TO TURN FOUR WEEKS INTO 48Hs Working on the Gardner engines at the Bus Depo in Leamore we had ample time to completely overhaul the 5 lw’s !!! I think ? Maybe 4weeks , I know that seams a long time ! But after stripping down the engine the cast iron crank case was in a bath of boiling Tricoethylene for 2days to clean out the black carbon that had built up inside especially round the cam shaft nooks and crannies , then it was hosed down ? And then only if Herbert Wolf said OK ? could i take it back to the cradle , The crank case was fitted out with White metal main bearings , this is where the skill came in !! The line boar was was set up and the cutting tool moved along turning out ribands of pure White metal, this took time to get (close) to the outer diameter of the crank Shaft using micrometers and then hand scraping of the bearings took place with engineers Blue until near perfection was obtained ,what a place to learn all skills ,this was just the bottom end ,The engines that came out where fantastic ,Then the 6 lw started to Arrive the main bearings where pre set no boring reg making the job easy’er but still built with pride ,from top to bottom calibration included ,What a difference from the modern engines today , Woking for GCC in Dammam we turned out ■■■■■■■ engine rebuild ,in some cases 48hrs for the oil fields in KSA , that including 8hr on the Dyno (we where flat out ) in 40deg Ron

Great posts Ron. Right up your street. What options for an engine rebuild did you have in the middle East? In the heat without air-conditioning it must have been challenging doing the detailed work with sweat running down your face.

Cheers

Johnny

Sent from my SM-G935F using Tapatalk

Johnny Options ? we had none How can you hide from the Sun , if I had the chance to take the Mac trucks out of that tin shed I would have , it was Unbearable to rebuild those engines in that heat , the only reason they where inside was because of the grinding sand that got every where , thats the last thing you need with rebuilding engines ,it was like an oven ,we would have been better outside at least we would have had air flow , So different from the Bus Depot where all the men sang , She wears Red feathers and a Hooly Hooly Skirt by Guy Mitchell , the Temp was good (the songs where great ,) Ron

The Bus Depo this was a long workshop , the clocking in time peace was at the entrance ? If you where more than 2 minutes late you could not start work until a 1/4 past . If you where more than a 1/4!! You had to wait till 9 ? Now I was late on numerous occasions, I had to walk up the workshop about 150yds long and was immediately spotted, by Len Lowe he was the first man to pass , he started banging his hammer on the steel bench !! Then this was picked up by the the Black smith ,Jack Wolf my mates dad , his striker Sam and the lads on the lathes then all the men may be 20 , Sid Turner ,Ray Dolman , Alfie Ward ,Gilbert Powell ! would start hammering on there steel work benches . Our engine cradle was right at the very top end under the glass office of the manager ■■■■ Richardson and Frank Clinton the foreman, Who by now was glaring out of his high position office , Herbert Wolf used to say burning the midnight oil Ron had a good time with a smile on his face , life was really good at this time a great place to work , Ron