Dunno then?:

Wheel Nut:

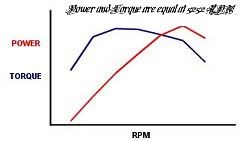

At 5252 RPM the Torque and Power are exactly the same.

Torque is turning force.

Power is about how much Work is being done by that Torque. You cannot have one without the other.

No engine has more horsepower than torque at 1600 rpm. It’s simply impossible.

No not true!

What?

Volvo FH12

Max Power 420hp @ 1750rpm

Max Torque 1475Lbft @ 1200rpm

A large diesel engine usually cannot get above 2,000 RPM, but has huge torque because of the long stroke. The torque is what lets your engine pull a heavy load up a hill.

The bigger the bang is what makes the crankshaft turn faster, but at what cost to fuel consumption. To get that big bang we have to feed the engine more food.

Without taking my horse outside and tying a weight of about 330 lbs to it and seeing if it can pull it up a slope in one minute. I will accept what I have already been told as a kid.

Explain yourself then!

Some important numbers;

Horsepower = torque X rpm / 5252

I am using proven mathematical facts from John Watt, Watt are you using?

“a strong horse could lift 150 pounds to a height of 220 feet in 1 minute.”

One horsepower is also commonly expressed as 550 pounds one foot in one second or 33,000

pounds one foot in one minute.

Three sets of numbers all saying the same thing.

5252 is the important number.

Torque is twisting or turning, of a wheel, a propshaft or a flywheel and all commonly

used as a comparison between engine output.

How to measure the capacity of a cylinder.

The cylinder bore x the cylinder stroke x the number of cylinders will give the swept

volume or cubic capacity of the engine.

Cylinder bore is measured using the mathmatical equation πr²

Ï€ = 3.1415926535 or 3.142 for simplicity

So in my example;πr² multiplied by 6.55(radius of the bore in cm) multiplied by 6.55

(radius of the bore in cm) multiplied by 15 (length of stroke in cm) (1 stroke = 180

degrees of the crankshaft)

So Volvo have actually had the badge on the door wrong for years;

Volvo FH12131.96895

using Volvos figures of a 131mm bore and a 150mm stroke

From these figures we can work out the compression ratio by adding the swept volume to

the volume of the combustion chamber plus the head gasket volume(thickness) plus the

piston deck height/ piston top volume and divided by the combustion chamber volume.

Thanks very much for letting me exercise my brain, it kept me out of the pub on a bank

holiday.