Although sequental gearchanges at all times with a modern truck especaly with a 12 or 16 speed box is a bit of overkill in most situations.

More a thing of the gardner david brown era ![]()

![]()

newmercman:

How is dropping two gears sequential ffs

I was actually referring to the idea of keeping the the revs as high as possible ![]() not the idea of letting the revs drop to 1,500 before downshifting. In which case the advice there seems to contradict itself in saying ( rightly ) that the best engine braking effort is applied at over 2,000 rpm but then says let the revs drop to 1,500 before downshifting.Let alone the modern idea of just leaving it in top and using the brakes and then block changing at the end.

not the idea of letting the revs drop to 1,500 before downshifting. In which case the advice there seems to contradict itself in saying ( rightly ) that the best engine braking effort is applied at over 2,000 rpm but then says let the revs drop to 1,500 before downshifting.Let alone the modern idea of just leaving it in top and using the brakes and then block changing at the end. ![]()

![]()

![]() Which is what I meant by the idea of ‘sequential’ downshifts in this case.As in all cases as you know my idea says that a transmission needs to be used as close to being a CVT as possible and that applies wether it’s using ‘plenty’ of upshifts to keep the thing around peak torque or plenty of downshifts to keep it as close as possible to the best effective engine speed to make an exhaust brake work properly ( which of course doesn’t mean using every single gear but is a lot closer to the meaning of ‘sequential’ than block changing is ).

Which is what I meant by the idea of ‘sequential’ downshifts in this case.As in all cases as you know my idea says that a transmission needs to be used as close to being a CVT as possible and that applies wether it’s using ‘plenty’ of upshifts to keep the thing around peak torque or plenty of downshifts to keep it as close as possible to the best effective engine speed to make an exhaust brake work properly ( which of course doesn’t mean using every single gear but is a lot closer to the meaning of ‘sequential’ than block changing is ). ![]()

You will get better engine braking with an engine brake by stretching it out, within the blue band of course, rather than keeping it in a tight RPM range. They are compression brakes so more compression is built up that way.

Maximum braking power is achieved at 2300rpm and each gear increases revs by 400rpm so in theory yes, changing down at 1900 would be the best option but for every second you’re changing gear you’re coasting without any stopping power at all so the increased braking power achieved by dropping gear at 1900rpm is somewhat lost by the time spent actually dropping a gear.

I just find it easier to double drop at 1500rpm.

You’re doing it the right way for the right reasons Terry…

Terry T:

Maximum braking power is achieved at 2300rpm and each gear increases revs by 400rpm so in theory yes, changing down at 1900 would be the best option but for every second you’re changing gear you’re coasting without any stopping power at all so the increased braking power achieved by dropping gear at 1900rpm is somewhat lost

That’s what I was saying.It’s then just an issue how fast the change can be made in order to minimise the time between gears.

You gear jamming on the kitchen floor again Geoffrey ![]()

![]()

Our ERFs have 3 stage jakes on the m11 is on auto and the 14l on floor pedal with no micro switchs or auto rev cut outs both have twin splits the jake is excellent for getting the revs down in order to change down.

Blipping the throttle is a bit Paddy Hopkirk, but there is nothing wrong with allowing the engine speed to match the propshaft and layshaft speeds. If you dont you will hear that awful whining as the synchro cones and baulk rings fight to catch up.

As for slipping the clutch, you would only stall if you just “dropped it.”

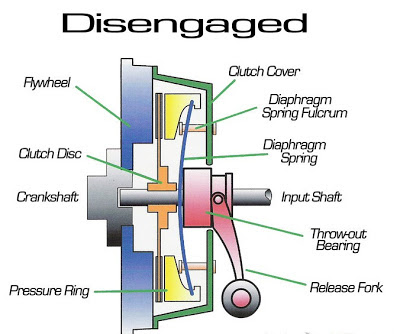

People used to argue whether you let the clutch in or out which is educational. You let the clutch pedal out and the Driven disc is held by friction between the flywheel and the pressure plate which then turns the gearbox.

With improved friction materials and engine management systems the actual slip time is much less than in the days of old when AEC and ERF where the king of the road. Apart from the actual friction material changing not much else has changed from the early days. Flywheels and plates have got lighter and smaller, but stronger and more reliable.

True, but temperature kills clutches and the bigger the speed differential between flywheel and pressure plate, the more slip and higher temperature.

Getting the RPMs matched in any gearchange, in any gearbox is paramount in getting good life from a clutch, in a synchro box it’s all done by the synchro rings.

This is why a clutch in a synchro box and a properly driven constant mesh box will last the same time.

Exactly and if you treat the change in a synchro box in a similar manner ie changing it the right revs and sloting the next gear im at the right time gou will get a lot lighter and smoother change with a synchro box than trying to smash it in to gear.

I know scania offer a clutch saver on manual tippers to hekp from pull away but at the same time can balls you up on a wet tip.

Melchett:

Out of interest, how does blipping the throttle “look after” the clutch?

Because:

newmercman:

temperature kills clutches and the bigger the speed differential between flywheel and pressure plate, the more slip and higher temperature.

Melchett:

Big Joe:

All auto box’s blip the throttle to save on clutch wear and in the right hands will easily exceed a million kms on the first clutch,As has been said already, auto boxes blip the throttle because they are automated “crash” boxes…there is no synchromesh to match the gear speeds so the ecu has to do it in the same way the driver had to when crash boxes were the norm.

It’s nothing to do with the clutch.

There maybe no syncro on upto date auto’s, but earlier versions still had syncro’s, and they also matched flywheel speed to clutch plate speed. Its all about mechanical sympathy and making the clutch last longer by ensuring that when it comes into contact with the flywheel they are both rotating at the same speed and not causing the clutch to wear away.

Ok so if your ment to blip in between gears why have we progressed from constant to synchro box’s? Also lets justremind ourselves that there’s only a hand full of us that actually drive new manual lorries.

Saaamon:

Ok so if your ment to blip in between gears why have we progressed from constant to synchro box’s?

Your not meant to, its just optional and mechanical etiquette if you’ve any sympathy for the driveline ![]()

You shouldn’t blip between gears in a synchro box, there’s no advantage unless you’re going down a lot of gears and even then you have to time the blip to perfection or it’ll do no good at all.

newmercman:

You shouldn’t blip between gears in a synchro box, there’s no advantage unless you’re going down a lot of gears and even then you have to time the blip to perfection or it’ll do no good at all.

But what if you blip after selecting the gear, the syncros have done their work and theres only the speed mismatch between the flywheel and clutch plate to iron out. Maybe blip is the wrong word ? as it does not aptly describe the notion of trying the match the revs to the next gear for a satisfyingly silky smooth gearchange ![]()

newmercman:

temperature kills clutches and the bigger the speed differential between flywheel and pressure plate, the more slip and higher temperature.

Big Joe:

There maybe no syncro on upto date auto’s, but earlier versions still had syncro’s, and they also matched flywheel speed to clutch plate speed. Its all about mechanical sympathy and making the clutch last longer by ensuring that when it comes into contact with the flywheel they are both rotating at the same speed and not causing the clutch to wear away.

Sorry but you need to go away & look into how this stuff works, synchromesh has nothing to do with the clutch at all!

Melchett:

newmercman:

temperature kills clutches and the bigger the speed differential between flywheel and pressure plate, the more slip and higher temperature.Big Joe:

There maybe no syncro on upto date auto’s, but earlier versions still had syncro’s, and they also matched flywheel speed to clutch plate speed. Its all about mechanical sympathy and making the clutch last longer by ensuring that when it comes into contact with the flywheel they are both rotating at the same speed and not causing the clutch to wear away.Sorry but you need to go away & look into how this stuff works, synchromesh has nothing to do with the clutch at all!

Erm…I think you do ![]()

Big Joe:

Erm…I think you do

Really?

The clutch lives outside the gearbox, synchro lives inside… synchro can’t & doesn’t have any effect on the clutch, flywheel or engine speed, it matches gear speeds within the gearbox to enable a smooth change.

Try this howstuffworks.com/transmission4.htm it might help ![]()

tootman318:

Saaamon:

tootman318:

coiler:

Sidevalve:

Saaamon:

Carryfast:

Saaamon:

tootman318:

On any manual truck you should always match your engine revs to the gear selected, Basics really

Sorry what year is it again? Think you’ll find that you no longer need to do that on a modern synchromesh gearbox, reving in between gear changes is a waste of fuel… Do you even drive a manual lorry?

There’s nothing ‘modern’ about synchro boxes they’ve been available for years.The fact is the more of a mis match between road and engine speed the more stress the synchros are put under.That’s in addition to the extra stress that’s put through the drivetrain as a whole assuming you just force the downshift through with the engine at idle and then just let the clutch back in.

Im well aware that they’ve been around for a while now… So are you trying to say we should be reving in between downshifts then?

Well the Volvo i-shift does and that’s supposed to be a ■■■■ sight smarter than us drivers.

Go figure.

The Volvo I shift does not have synchro cones that why it has to rev between downshifts to match engine speed to gearbox speed otherwise the gears will crunch. That’s why it is lighter than a manual box.

Manual gearboxes are synchromesh so you don’t need to Match engine speed to gearbox.Another thing to think of when engine or exhaust braking is that your brake lights do not come on so there is no warning to drivers behind you that you are slowing.

Total ■■■■■■■■. The i shift is the old 12 speed full sync box but with modern air solenoids and software. Had mine from new 6 years ago and serviced by volvo and had all the i shift explained to me over that time. Obviously you know better and i take my hat off to you sir

Having done a very quick bit of research myself I think you’ll find that coiler is correct.

The i shift is a manual gearbox with optional auto or man operation as are most modern boxes. Also my brake lights come on when the exhaust brake is on. Has done from new!

When I first bought an I shift in 2003 it was explained to me that there was no synchro in it, that along with an Ali casing meant it was about 200kg lighter than the 12 speed manual. I have had the 03, an 05 and an 08 gearbox apart for repairs and there is no synchro in them.

Although I may make the odd mistake I will not post facts on this forum which I either know are either untrue or which I know nothing about.