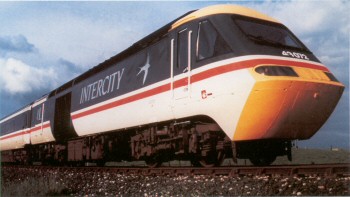

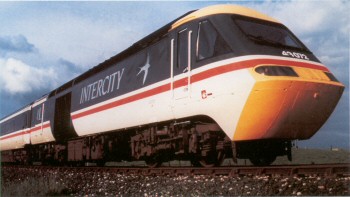

The Valenta and The High Speed Train (HST aka The Intercity 125)

One of Paxman’s greatest achievements in the field of rail traction was the success of its engines in the High Speed Train (HST), known to many as the Intercity 125. British Rail’s decision in the 1960s to build trains capable of operating at 125 mph posed major technical challenges. The power required for a train to travel at 125 mph is twice that needed to travel at 100 mph, the top speed of the fastest passenger expresses in the late 1960s. The loading gauge on the rail network determines the maximum width and height of any locomotive and therefore the maximum dimensions of any diesel engine inside it. This is not as generous as might first appear as there must be sufficient space round the engine to provide access for maintenance and repairs. One way of increasing power output within these restrictions is to build a longer engine with more cylinders, although there are practical limits to length, particularly for a high speed engine. The second alternative, used quite frequently at that time, is to install two engines in a locomotive. The problem with both these solutions is the heavier weight and axle loading of the locomotive. This is critical because heavy axle loadings at speeds over 100 mph lead to substantial track damage necessitating repairs which are both expensive and disruptive.

The ingenious solution was to put an engine in a power car at each end of the train, thus spreading the weight and keeping axle loadings within acceptable limits for the much higher operating speed. This arrangement offered other important advantages. In the event of engine failure in one power car, the other can provide sufficient power for the train to continue its journey at up to 100 mph (as mentioned above, the power required for 125 mph is twice that required for 100 mph). Moreover, the need to turn a locomotive round for a return journey is eliminated - the driver just has to walk along to the cab at the other end of the train.

In August 1970 the British Rail Board’s Investment Committee authorised the expenditure of £800,000 on the design, development and construction of a prototype High Speed Diesel Train. At the time Paxman had just embarked on development of its Valenta engine. This engine in its 12 cylinder form, as fitted to the HST, was rated at 2,250 bhp compared with the 1,200 bhp rating of the first 12 cylinder Venturas (its immediate predecessor) delivered for rail traction. The first two engines for the prototype HST were delivered in the Spring of 1972, the year the Valenta was formally launched on the market. The prototype HST itself was completed in May and started running the same year. A full Intercity 125 service was introduced in 1976 on British Rail’s Western Region. Trial running on the Eastern Region commenced in autumn 1977. A limited service on the East Coast Main Line began on 8th May 1978, with a full service being introduced in May 1979.

The total weight of an HST trainset, was a little over 350 tons. Each power car weighed 68 tons. The 2,250 bhp 12RP200 Valenta engine drove a flange mounted Brush 1480kW 1,500 volt traction alternator, a 480kW 850 volt train-supply alternator and a 33kW 110 volt power car auxiliaries alternator. The AC traction current was supplied to silicon rectifiers, from which the DC current was directed via switchgear to the DC traction motors. 197 of these Class 43 power cars were built at British Rail’s Crewe Works between 1975 and 1982. More than 230 Valenta engines were supplied for the HST and despite the very demanding environment they were able to operate for 20,000 hours between major overhauls. The HST was the only diesel-electric system in the world regularly operating at speeds of up to 125 mph. Under normal operating conditions, each power car travelled more than 1,000 miles in the course of an average 16 hour working day.

The total weight of an HST trainset, was a little over 350 tons. Each power car weighed 68 tons. The 2,250 bhp 12RP200 Valenta engine drove a flange mounted Brush 1480kW 1,500 volt traction alternator, a 480kW 850 volt train-supply alternator and a 33kW 110 volt power car auxiliaries alternator. The AC traction current was supplied to silicon rectifiers, from which the DC current was directed via switchgear to the DC traction motors. 197 of these Class 43 power cars were built at British Rail’s Crewe Works between 1975 and 1982. More than 230 Valenta engines were supplied for the HST and despite the very demanding environment they were able to operate for 20,000 hours between major overhauls. The HST was the only diesel-electric system in the world regularly operating at speeds of up to 125 mph. Under normal operating conditions, each power car travelled more than 1,000 miles in the course of an average 16 hour working day.

A good book about the HST, with plenty of photographs, is HSTs at Work by Roger Ford and Brian Perren, Ian Allen (ISBN 0 7110 1784 0).

Three World Records

The HST, powered by Paxman Valentas, broke speed records three times. The first was on 12th June 1973, when the prototype, just a year after it was built, established a world speed record for diesel traction at 143.2 mph (230.4 kph) between Northallerton and Thirsk on the East Coast main line.

Another world record was broken on 27th September 1985 when the Intercity 125 Tyne-Tees Pullman ran from Newcastle to London King’s Cross, a distance of 268 miles, in under 2 hours 20 minutes at an average speed of 115.4 mph. The 17.9 miles between Corby Glen and Werrington (near Peterborough) were run in 7 minutes 40 seconds, an average speed of 140.1 mph.

On 1st November 1987 the HST broke a world speed record for diesel traction for a third time, at a speed of 148.5 mph (239 kph) with peak speeds of just under 150 mph. This was achieved using power cars No. 43102 “City of Wakefield” and No. 43104 and three carriages over a measured mile between York and Northallerton. After being in service for 39 years, power car No. 43102 was withdrawn by East Midlands Railway in May 2021. It was donated to the National Railway Museum (NRM) and joined the NRM’s collection of high-speed diesel locomotives, such as the HST prototype power car No. 41001 and the English Electric DP1 ‘Deltic’ prototype, at the Locomotion railway museum in Shildon, County Durham.

Thermal Cycling

During the long hot summer of 1983 Valenta engines in HSTs suffered recurrent failures for which Paxman received a great deal of criticism. Several independent commentators later publicly acknowledged that much of this was undeserved. The problems were not unforeseen. In 1969, more than two years before the prototype HST first ran, the Institution of Mechanical Engineers published a paper on ‘Critical Factors in the Application of Diesel Engines to Rail Traction’ by W Petrook and W A Stewart. (14) The authors considered rail traction was more arduous than other diesel engine applications because the ‘on-off’ nature of the engine duty cycle resulted in more severe thermal cycling. Engines spent much of their time idling and were then required to accelerate quickly to full output. In normal fast passenger service operation engines were on full load for 45% of the time, and idling for another 45% of it. Only 10% of their time was on intermediate conditions of power output. On average there was a change in power approximately every five minutes or six complete cycles of going from idling to full power and back to idling every hour. The authors argued it was the sudden reduction in power, rather than the sudden increase, which was the main problem in thermal cycling, and that it was this sudden cooling which subjected the engine to the highest thermal load. The most critical factor, they said, was the ability of highly rated turbocharged and charge-cooled (intercooled) engines to withstand the effect of rapid power cycling. Petrook and Stewart also made reference to the difficulties of accommodating adequate cooling systems for intercooled engines, the fact that only 38% of the heat produced by the engine was converted to useful work - the rest has to be dissipated, and that on British Railways the greatest trouble affecting diesel locomotive reliability was the cooling system, trouble usually associated with leaks. On the general issue of reliability they noted that many diesel engine components which were ‘tried and tested’ under only slightly different conditions failed in railway service.

The spate of overheating problems, engine shutdowns, coolant leaks, and component failures experienced in 1983 was due to a combination of the high ambient temperatures that summer and issues identified by Petrook and Stewart in 1969: severe thermal cycling, cooling system deficiencies and leaks.

The HST was designed for long distance express services with few stops, on which it was anticipated the engine would run at constant speeds for most of the time. The reality was very different. The HST became a 125 mph train running tightly scheduled services on a rail system designed for a maximum of 100 mph. On routes where slower trains could run at almost constant speeds, drivers were constantly accelerating hard to regain maximum speed, or rolling along at notch 1 or 2 at speed, or braking. The average time on full power was just 2 minutes. On average, engines were going through the cycle of idling to full power and back to idling once every 6 minutes, equating to 160 cycles in a normal working day.

The thermal efficiency of the Valenta is about 40%. When on full power it delivers 2,250 bhp but another 3,000 bhp of waste energy is generated which rapidly heats up the engine to its normal full load operating temperature. After two minutes or so the power is shut off and the engine cools down. This constant heating and cooling, and the associated expansion and contraction of components, led to cracking, fatigue problems, and leaks. (Caused particularly by the different rates of expansion of adjoining components of different materials, e.g. steel and aluminium alloy.) Affected areas were cylinder liner top and bottom joints, exhaust manifolds, and turbocharger inlet casings. At full power the latter two items were subjected to exhaust temperatures of 600° C.

Reasons for the high rate of failures were initially sought in the engine itself, but the number of failures during periods of high ambient temperature led to examination of the performance of the cooler group which was neither designed or supplied by Paxman. The cooling system of an HST power car has two closed circuits each with a pair of radiators. The coolant in the primary circuit runs through the engine block, exhaust manifolds, and turbocharger casing. That in the secondary circuit runs through the charge air and lubricating oil coolers. A variable speed fan driven from the free end of the engine draws cool air through the radiator panels of the secondary circuit before forcing it through the radiators of the primary circuit.

The causes of overheating, which made the thermal cycling even more severe, were traced to internal and external blockages in the cooling system. Internally the flow of coolant through the primary circuit radiators was obstructed by a silicone based jointing compound. This had been used to seal joints between cylinder liners and the top deck of the crankcase but in excessive quantities. Pieces of sealant were broken off by the flow of coolant and carried through the system until becoming trapped in the top of the radiators. The use of the jointing compound was discontinued. External blockages were basically down to poor maintenance. Ballast dust, seeds, and other fine debris built up between radiator fins reducing the air flow. The problem was worse on the primary circuit radiators because oil from small leaks in fan drive components combined with this fine debris to make a sticky mass which was not properly removed by the cleaning methods used at the time. These involved spraying high pressure water onto the radiator panels with a narrow spray angle gun. The technique, together with physical knocks during cleaning, distorted cooling fins thus reducing air flow even further.

An improved regime of radiator maintenance did much to bring the overheating problems under control. With some additional design work on cylinder liner joints, turbocharger casings, and to improve coolant flow in a few critical areas of the engine, the problems were largely resolved by 1985. After that the engine had an exceptional record of reliability in a punishing environment. Overhaul intervals became about twice as long as those originally planned. In 1985 HST power cars were averaging 220,000 miles a year, more than twice that of any other diesel-electric set operated by British Rail. Again, one should remember what enormous engineering advances were involved in the HST and the Valenta. It was not surprising that some problems were encountered but these should not detract from the technical achievements. Roger Ford, a highly respected commentator on railway matters, noted in 1985 the “HST is the best and fastest diesel train in the world which does a job no other country’s engineers have even tried to tackle”.

The total weight of an HST trainset, was a little over 350 tons. Each power car weighed 68 tons. The 2,250 bhp 12RP200 Valenta engine drove a flange mounted Brush 1480kW 1,500 volt traction alternator, a 480kW 850 volt train-supply alternator and a 33kW 110 volt power car auxiliaries alternator. The AC traction current was supplied to silicon rectifiers, from which the DC current was directed via switchgear to the DC traction motors. 197 of these Class 43 power cars were built at British Rail’s Crewe Works between 1975 and 1982. More than 230 Valenta engines were supplied for the HST and despite the very demanding environment they were able to operate for 20,000 hours between major overhauls. The HST was the only diesel-electric system in the world regularly operating at speeds of up to 125 mph. Under normal operating conditions, each power car travelled more than 1,000 miles in the course of an average 16 hour working day.

The total weight of an HST trainset, was a little over 350 tons. Each power car weighed 68 tons. The 2,250 bhp 12RP200 Valenta engine drove a flange mounted Brush 1480kW 1,500 volt traction alternator, a 480kW 850 volt train-supply alternator and a 33kW 110 volt power car auxiliaries alternator. The AC traction current was supplied to silicon rectifiers, from which the DC current was directed via switchgear to the DC traction motors. 197 of these Class 43 power cars were built at British Rail’s Crewe Works between 1975 and 1982. More than 230 Valenta engines were supplied for the HST and despite the very demanding environment they were able to operate for 20,000 hours between major overhauls. The HST was the only diesel-electric system in the world regularly operating at speeds of up to 125 mph. Under normal operating conditions, each power car travelled more than 1,000 miles in the course of an average 16 hour working day.